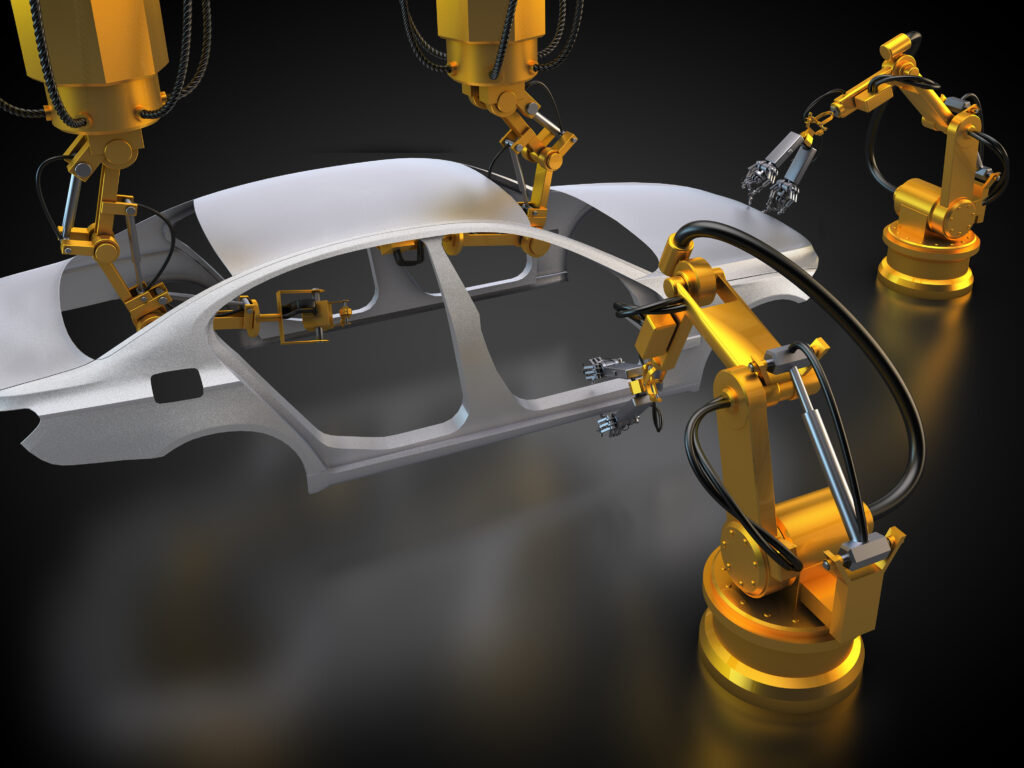

The global automotive industry is preparing for its massive expansion in the foreseeable future. The industry has undergone an enormous transformation due to the numerous technological advances invented and incorporated. Leaders and management teams must frequently make critical decisions about improving the efficiency of an organization’s operations. Nowadays, the global demand for autonomous electric vehicles is increasing. So, in these changing times, acquiring an Enterprise Resource Planning (ERP) system is a need for the manufacturing industry!

What do you understand about the term ERP?

ERP is a modern tool to manage business process software. ERP for manufacturing industry enables automotive owners to manage their critical auto parts prudently, schedule and plan workstations, and control BOM flow. The systems can add more value to organizations by optimizing operations. It can help you reduce costs and maximize profits to a greater extent.

What are the Upsides of using ERP in the automotive industry?

Automotive ERP has evolved itself in recent times. It assists each manufacturer in dealing with the rapidly changing industry in their unique way. You can also look forward to capitalizing on changing business environments. In the automotive industry, ERP technology strives to improve operational efficiency. Several other key benefits are listed as follows:

- Lower Costs

ERP for automotive industry This will help your organization consolidate most of the software fragments it currently uses. Further, manufacturers do not require multiple servers or a team of IT professionals to install and configure ERP systems when hosted in the cloud.

- Higher ROI

An ERP solution integrates several systems into a single user interface. It includes product development and finance. Further, you can also manage the supply chain, customer relationships, inventory, and other functions. You can avail an improved customer satisfaction with increased visibility and optimized production.

- Optimization of Resources

Effective automotive ERP software ensures that each resource and employee contributes to lowering the time wastage and boosting profitability. Furthermore, it allows the manufacturers to view, edit, and manage all the resources in a single place.

- Better communicative collaboration

You do not need to manually combine data from various software systems and processes upon installing the ERP system. The management can have a comprehensive and secure view of production and quality control. Further, they also look after human relations and supply chain management, including procurement, shipping, finance, warehouse, etc.

- Increased Compliance

Detailed labeling is a crucial factor in meeting quality parameters. It also takes the accepted and rejected quality levels into consideration. ERP developers are aware of the automotive industry’s quality standards. They make timely decisions by tracking sample frequencies and production defects, and by viewing and executing the quality plan.

- Security and Safety of Data

Manage all the information, from reports to customer data, in an end-to-end process on a single system through ERP. When you deploy an ERP with regulatory compliance modules, you can make this obstacle less daunting to a much greater extent. You can generate and manage secure reports for submission, adhering to the appropriate regulatory bodies.

- A Quality Customer Service

ERP systems It integrates well with managing your customer relationship. So, you can now easily integrate your marketing tasks. You can reach out to a larger online audience, and nurture your leads captured in your sales funnel. Furthermore, they also improve your ability to meet your customers’ needs.

- Management of The Inventory

No one wants to make a surplus inventory willingly. The stock-outs can interfere with customer needs. So, the inventory and warehouse operations need special attention. Eresource Xcel ERP system for automotive industry simplifies report generation, warehouse transfer recording, inventory capture, and task and transaction processing on the plant floor.

- Increased Data Access in Real-Time

Users of modern ERP systems can streamline information flow within an organization. It calls for quick, enhanced, and informed decision-making with cumulative data collected from all departments. Manufacturers in the automotive industry must keep up with the most up-to-date information. ERP helps them track the records of customers. Further, you can also look into the availability of resources, management of employees, and manufacturing status with the help of ERP software.

Wrapping Up

The Enterprise Resource Planning (ERP) software is a significant breakthrough in many automotive manufacturing industries. It allows automotive equipment manufacturers to smoothly and efficiently manage their business processes, resulting in higher productivity and progress. Automotive ERP software will continue to modernize and make deeper inroads into the industry with a significant impact.

Also Read – ERP Software in Mumbai

Categories

Register for Free Demo!

Recent Post

-

eresource ERP 360 - an

11th Apr 2019 -

A competitive ERP system for

17th Apr 2019 -

Auto components manufacturing industry has

17th Apr 2019 -

Make the best use of

17th Apr 2019