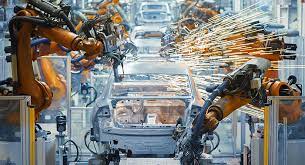

With the automobile industry estimated at $82.6 billion in the United States, it can be easily said that this sector is one of the most massive operations in the country. Not only in the US, but the industry is also growing globally. However, with the vastness of the automobile industry, companies involved in researching, designing, manufacturing, and selling vehicles face several complexities.

ERP for Automotive Industry is a proven solution for automobile enterprises looking for ways to streamline their business operations and overcome challenges. You can get your hands on ERP software featuring powerful and strategic business process management tools to assist in managing crucial business data. But keep in mind that not all ERP platforms are designed the same and, thus, suitable for automobile companies.

In this article, we’ve enlisted some tips considering which will help you choose the best ERP system for the automobile sector.

- Company Readiness

Before you search for suitable ERP software, ensure your organization is equipped with the resources required for supporting the software. These resources can include financial and human resources. Moreover, managers should ensure the company and employees are prepared for new infrastructural change.

You need to realize that adopting an ERP system requires lots of time and effort. You should implement the ERP platform when your company has the space, resources, time, and readiness to embrace and adapt to this new change.

- Select the Right Service Provider

You can find hundreds of ERP software providers in today’s innovative market. However, you need to choose the most suitable provider for your automobile company based on the business’s standards and requirements.

It is one of the most crucial tips to consider because the wrong Manufacturing ERP Software not matching your factory standards can negatively impact your business. It could further affect the rate of operations, and such an ERP platform can become complicated to handle for employees without reaping any benefits.

Also Read – Cosmetics ERP Software

- Services Provided by ERP System

Other than a few essential services provided by the ERP system providers, many ERP solution providers are capable of offering features and facilities specifically suitable to automobile companies. Only after evaluating the features and facilities and your company’s requirements should you select an ERP system provider.

Usually, an ERP system featuring workstation scheduling, competition monitoring, inventory management, SCM, and OEM is considered most useful for automobile enterprises.

- The versatility of the ERP Software

An ERP system should be flexible enough to scale up or down with changing demand for vehicles in the market. Moreover, these systems must be accessible from any device at any time, giving you much freedom when using ERP software. A versatile ERP platform will allow you to carry out different processes simultaneously.

- Security of the ERP Platform

Now that ERP systems are designed to store sensitive business information at a single, centralized platform, it’s crucial to check its security level. The system’s level of security will help you determine the risk of data loss or theft.

In addition, check if the ERP system provides a secured cloud backup of your business data. Implementing such a system will help you keep your data safe and prevent it from being lost. Usually, a cloud-backed, robust ERP system features automatically scheduled backups to avoid data loss and failure. Always remember to choose the ERP software provider who can manage the data security, updates, and storage.

- Helping with Regulations Compliance

Among several industries, the automobile industry is one of the most regulated, given the link between vehicles, human safety, and the environment. Therefore, this should be a vital consideration for an automobile company as it selects the suitable ERP platform for business needs. Choosing ERP software that can help auto companies comply with industry standards and regulations is recommended.

Final Thoughts!

As the erp for manufacturing industry continues to expand and change, companies need to leverage the best technology solutions, especially ERP systems, to take advantage of growth opportunities. An ERP platform can help auto businesses increase revenue, retain customers, better financial statements, streamline manufacturing processes, reduce cost, automate operations, and more.

However, not all ERP solutions have features helpful for the auto industry. These tips will aid you get the best ERP solution to meet all your business needs.

Also Read – ERP for Power Industry