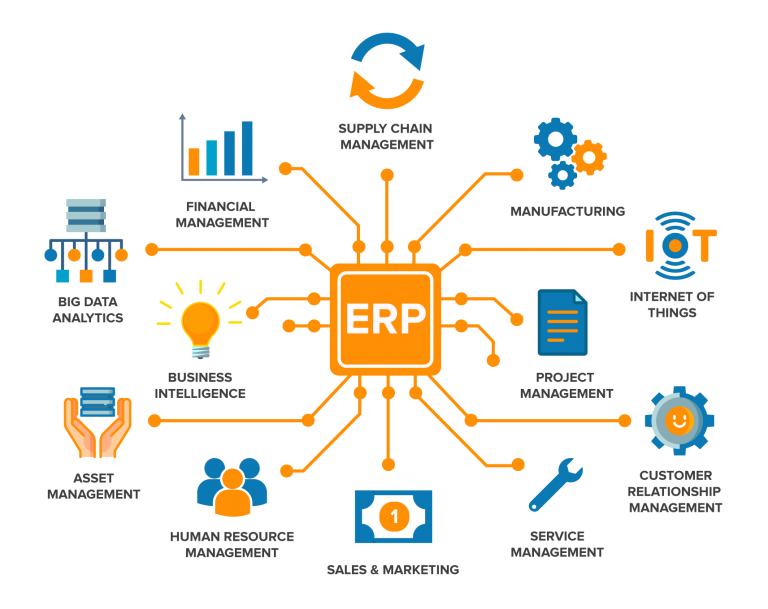

Manufacturing ERP (Enterprise Resource Planning) is a specialized software solution specifically designed to streamline and optimize the intricate operations of manufacturing companies. By integrating various functionalities such as inventory management, production planning, shop floor management, supply chain management, finance, human resources, and customer relationship management, ERP creates a unified system. The primary objective of Manufacturing ERP is to enhance operational efficiency, minimize costs, and boost overall productivity.

One of the key advantages of Manufacturing ERP is its ability to provide visibility into critical company information. By consolidating data from different departments into a centralized system, ERP enables businesses to access and analyze information in real-time. This empowers companies to make informed decisions promptly, contributing to faster and more effective decision-making processes.

What is the reason for Using ERP Software for Manufacturing

ERP software for manufacturing is specifically designed to cater to the unique requirements and challenges encountered by manufacturers. Its purpose is to streamline operations, enhance visibility, and facilitate data-driven decision-making by leveraging real-time information. By integrating different departments, different divisions and functionalities, ERP software fosters efficient collaboration, optimizes resource allocation, and enables effective inventory management. The ultimate result is improved productivity and heightened customer satisfaction.

What are the Benefits of Manufacturing ERP Software:

ERP software brings numerous benefits to the manufacturing industry, enhancing its operational efficiency and overall success. In addition to the existing content, here’s a revised version with added benefits of eresource ERP software:

- Streamlined Operations: eresource ERP software simplifies and automates core manufacturing processes, reducing manual effort and minimizing errors. This streamlining leads to improved efficiency and productivity throughout the organization.

- Enhanced Inventory Management: With eresource ERP, manufacturers gain accurate real-time data that enables optimal inventory management. By maintaining optimal inventory levels, minimizing stockouts, and improving supply chain efficiency, eresource ERP ensures smooth production processes and timely deliveries.

- Improved Planning and Scheduling: eresource ERP empowers manufacturers with effective production planning, scheduling, and resource allocation capabilities. This optimization of resources and assets results in better utilization, reduced downtime, and improved on-time delivery performance.

- Increased Cost Control: eresource ERP software provides detailed insights into costs across various aspects of manufacturing operations. By analyzing this data, manufacturers can identify areas of improvement, eliminate wasteful practices, and implement cost-saving measures, leading to enhanced profitability.

- Better Decision Making: eresource ERP offers integrated reporting and analytics capabilities that provide valuable insights into key performance indicators and manufacturing metrics. These insights enable management to make data-driven decisions, improving overall strategic planning and fostering continuous improvement.

- Streamlined Communication and Collaboration: eresource ERP facilitates seamless communication and collaboration among different departments and teams within the manufacturing organization. This integration eliminates information silos, enhances coordination, and fosters effective teamwork, resulting in improved operational efficiency.

- Regulatory Compliance: eresource ERP software includes features to ensure compliance with industry regulations and standards. It helps manufacturers track and adhere to various compliance requirements, ensuring legal and regulatory obligations are met.

- Enhanced Customer Satisfaction: By streamlining operations, optimizing inventory levels, and improving on-time deliveries, eresource ERP software contributes to better customer satisfaction. With accurate information readily available, manufacturers can respond quickly to customer inquiries, provide accurate order status updates, and deliver products on time, strengthening customer relationships.

Incorporating eresource ERP software into manufacturing operations brings a multitude of benefits, ranging from streamlined operations and enhanced inventory management to improved decision-making and cost control. These advantages contribute to the overall success and competitiveness of manufacturing companies.

Key Features of Manufacturing ERP Software:

Manufacturing companies require robust software solutions to streamline their operations and achieve optimal efficiency. eresource XCEL ERP for manufacturing offers a comprehensive suite of features designed to meet the specific needs of the industry. In addition to the existing content, let’s explore the key features of eresource XCEL ERP that empower manufacturers to excel in their operations.

- Production Planning and Scheduling: With eresource XCEL ERP, manufacturers can effectively plan and schedule their production activities. The software provides tools to optimize resource allocation, manage work orders, track progress, and ensure timely deliveries.

- Inventory Management: eresource XCEL ERP enables manufacturers to efficiently manage their inventory. It provides real-time visibility into stock levels, automates inventory tracking, facilitates accurate demand forecasting, and ensures optimal inventory control.

- Supply Chain Management: eresource XCEL ERP incorporates robust supply chain management features. It enables manufacturers to streamline their procurement processes, manage vendor relationships, track shipments, and ensure timely delivery of materials.

- Quality Control and Assurance: The ERP software includes modules for quality control and assurance. It helps manufacturers implement quality standards, track product quality throughout the production process, perform inspections, and manage non-conformance issues.

- Financial Management: eresource XCEL ERP offers comprehensive financial management capabilities tailored to the manufacturing industry. It facilitates budgeting, cost control, expense management, financial reporting, and supports compliance with accounting standards.

- Sales and Order Management: The ERP software streamlines the sales and order management process. Manufacturers can efficiently manage customer orders, track order status, generate accurate invoices, and streamline the sales cycle from lead to fulfillment.

- Human Resources Management: eresource XCEL ERP includes features for human resources management. It helps manufacturers manage employee data, track attendance, automate payroll processes, and streamline HR operations.

- Customer Relationship Management (CRM): The CRM module in eresource XCEL ERP allows manufacturers to effectively manage customer relationships. It enables sales and customer service teams to track interactions, manage leads, and provide personalized support to enhance customer satisfaction.

- Real-time Reporting and Analytics: eresource XCEL ERP provides real-time reporting and analytics capabilities. Manufacturers can generate insightful reports, access key performance indicators (KPIs), and gain actionable insights to make data-driven decisions.

- Business Intelligence: eresource XCEL ERP incorporates business intelligence tools that empower manufacturers with advanced analytics and visualization capabilities. It enables them to identify trends, analyze performance, and uncover opportunities for continuous improvement.

By leveraging the key features of eresource XCEL ERP for manufacturing, businesses can optimize their operations, achieve better control over their processes, enhance decision-making, and ultimately drive productivity and growth.

What are the modules of ERP for the Manufacturing Industry:

Manufacturing ERP software is designed to address the unique requirements of the manufacturing industry, providing a comprehensive suite of modules that cater to different aspects of the manufacturing process. eresource ERP software offers a range of modules tailored to enhance operational efficiency and streamline manufacturing operations. In addition to the existing content, let’s explore the specific modules of eresource ERP software that empower manufacturers to excel in their operations.

- Material Requirement Planning (MRP): The MRP module in eresource ERP enables manufacturers to effectively plan and manage their material requirements. It facilitates accurate forecasting, automates procurement processes, optimizes inventory levels, and ensures timely availability of materials for production.

- Bill of Materials (BOM): The BOM module in eresource ERP provides manufacturers with a centralized repository for managing and tracking the components and sub-assemblies required for production. It allows for efficient BOM creation, revision control, and accurate costing of products.

- Shop Floor Control: The Shop Floor Control module in eresource ERP enables manufacturers to effectively manage and monitor their shop floor activities. It provides real-time visibility into production processes, tracks work orders, captures labor and machine data, and facilitates efficient resource utilization.

- Product Lifecycle Management: eresource ERP includes a PLM module that allows manufacturers to manage the entire lifecycle of their products. It facilitates collaborative product design, engineering change management, version control, and documentation management, ensuring effective product development and innovation.

- Advanced Planning and Scheduling (APS): The APS module in eresource ERP enables manufacturers to optimize their production planning and scheduling processes. It takes into account various constraints, such as resource availability, capacity, and order priorities, to generate optimal production plans and schedules.

- Warehouse Management System (WMS): eresource ERP incorporates a WMS module that helps manufacturers efficiently manage their warehouse operations. It streamlines receiving, put-away, picking, packing, and shipping processes, improves inventory accuracy, and enables effective warehouse space utilization.

- Plant Maintenance: The Plant Maintenance module in eresource ERP allows manufacturers to effectively manage their plant assets and equipment. It facilitates preventive maintenance planning, work order management, asset tracking, and maintenance history tracking, ensuring optimal equipment performance and minimizing downtime.

By utilizing the modules of eresource ERP software, manufacturers can optimize their operations, enhance productivity, improve resource utilization, and achieve better control over their manufacturing processes.

Also Read – ERP for project based company

What are the Challenges of the Manufacturing Industry:

The manufacturing industry faces various challenges that can impact its operations and overall success. These challenges arise from a combination of internal and external factors, requiring manufacturers to adapt and find effective solutions. Here are some of the major challenges faced by the manufacturing industry:

- Global Competition: Manufacturers operate in a highly competitive global market. They face competition from both domestic and international companies, requiring them to continuously innovate, improve efficiency, and deliver high-quality products at competitive prices.

- Supply Chain Complexity: The manufacturing process involves a complex network of suppliers, distributors, and logistics providers. Managing the supply chain efficiently, coordinating with multiple stakeholders, ensuring timely delivery of materials, and minimizing disruptions pose significant challenges.

- Rapid Technological Advancements: Technology is advancing at an unprecedented pace, and manufacturers must keep up with the latest developments to remain competitive. Embracing new technologies, such as automation, robotics, artificial intelligence, and IoT, while ensuring compatibility with existing systems, can be a challenge.

- Quality Control and Compliance: Maintaining consistent product quality and meeting regulatory compliance standards is crucial for manufacturers. Ensuring adherence to quality standards, managing product certifications, and navigating complex regulatory requirements can be demanding and time-consuming.

- Rising Operational Costs: Manufacturers face the challenge of managing operational costs, including raw materials, energy, labor, and overhead expenses. Fluctuations in commodity prices, wage hikes, and increasing energy costs can impact profit margins, requiring effective cost management strategies.

- Talent Acquisition and Retention: Finding and retaining skilled talent is a persistent challenge for the manufacturing industry. As experienced workers retire and technological advancements demand new skill sets, attracting and retaining qualified personnel becomes crucial for maintaining productivity and driving innovation.

- Changing Customer Demands: Customer expectations and preferences are constantly evolving. Manufacturers must be agile and responsive to changing market demands, customization requests, shorter product life cycles, and the need for sustainable and eco-friendly solutions.

- Risk Management: Manufacturers face various risks, including supply chain disruptions, natural disasters, cyber threats, and regulatory changes. Implementing effective risk management strategies, ensuring business continuity, and safeguarding critical data and intellectual property are vital considerations.

- Sustainability and Environmental Impact: With increasing awareness of environmental issues, manufacturers must address sustainability concerns. Implementing eco-friendly practices, reducing carbon footprint, and incorporating sustainable materials and processes pose challenges in balancing environmental responsibility with profitability.

- Innovation and Product Development: Continuous innovation is key to staying competitive in the manufacturing industry. Developing new products, improving existing ones, and staying ahead of market trends require dedicated research and development efforts, collaboration, and investment in innovation capabilities.

Navigating these challenges requires a proactive approach, strategic planning, investment in technology and talent, effective supply chain management, and a commitment to continuous improvement. Manufacturers that can successfully address these challenges have the opportunity to thrive in a dynamic and evolving industry.

Who Needs Manufacturing ERP Software? Manufacturing ERP software is beneficial for a wide range of organizations, including small, medium, and large-scale manufacturers across various industries. It caters to businesses seeking to improve operational efficiency, optimize resources, enhance inventory control, and achieve better coordination among departments.

When is a manufacturing company ready to start using ERP software?

Implementing an ERP (Enterprise Resource Planning) software system can be a significant decision for a manufacturing company. It requires careful consideration and preparation to ensure a smooth transition and maximize the benefits of the software. So, when is a manufacturing company ready to start using ERP software? Let’s explore the key indicators that signify readiness for ERP implementation.

- Process Complexity: As a manufacturing company grows, its processes become more complex. If your company is experiencing challenges in managing multiple departments, coordinating workflows, and ensuring accurate data flow between different functions, it may be an indication that ERP software can streamline operations and improve efficiency.

- Data Discrepancies and Inefficiencies: Are you encountering inconsistencies and inaccuracies in data across various systems and departments? If data duplication, manual data entry errors, and inefficient data sharing are causing delays, errors, and hindering decision-making processes, ERP software can centralize data management, improve data accuracy, and enhance overall productivity.

- Business Expansion: When a manufacturing company expands its operations, either by adding new locations, increasing product lines, or targeting new markets, managing the increased complexity becomes a challenge. ERP software can provide a scalable solution to support the company’s growth, standardize processes, and enable efficient resource allocation.

- Inventory Management Challenges: If your manufacturing company is struggling with inventory control, experiencing stockouts or excess inventory, or facing difficulties in tracking materials and components, ERP software with integrated inventory management features can optimize inventory levels, ensure accurate demand forecasting, and streamline procurement processes.

- Ineffective Communication and Collaboration: Lack of seamless communication and collaboration among departments can hinder productivity and lead to delays in decision-making. If your manufacturing company is experiencing siloed information, inefficient communication channels, and difficulties in coordinating activities, ERP software can facilitate real-time data sharing, improve collaboration, and enhance overall communication efficiency.

- Compliance and Regulatory Requirements: Manufacturing companies operate in a regulated environment with specific compliance requirements. If your company struggles to meet regulatory standards, ensure traceability, and maintain proper documentation, an ERP system with built-in compliance features can automate compliance processes, streamline audits, and mitigate risks.

- Customer Expectations: Meeting customer expectations is crucial for manufacturing companies. If your company is facing challenges in delivering products on time, providing accurate order status updates, or addressing customer inquiries effectively, ERP software with integrated customer relationship management (CRM) features can enhance customer satisfaction, improve response times, and strengthen customer relationships.

- IT Infrastructure Limitations: Outdated or disjointed IT infrastructure can hinder growth and productivity. If your manufacturing company is relying on disparate systems that are difficult to maintain, lack integration capabilities, and impede data accessibility, implementing an ERP system can consolidate IT infrastructure, streamline processes, and provide a unified platform for data management.

Considering these indicators can help manufacturing companies determine if they are ready to start using ERP software. It is essential to assess the company’s current challenges, future goals, and evaluate the capabilities and features offered by ERP solutions. By carefully planning and preparing for ERP implementation, manufacturing companies can position themselves for enhanced efficiency, improved decision-making, and sustained growth in the dynamic manufacturing industry.

How does Manufacturing ERP Software solution work?

Manufacturing ERP software solutions work by integrating and streamlining various aspects of a manufacturing company’s operations into a unified system. Here’s a unique explanation of how Manufacturing ERP software solution works:

- Centralized Data Management: Manufacturing ERP software acts as a central repository for all crucial data related to the manufacturing process. It consolidates information from different departments such as production, inventory, procurement, finance, and customer management, ensuring that data is accurate, up-to-date, and accessible in real-time.

- Automation and Process Optimization: ERP software automates and optimizes key manufacturing processes, reducing manual effort and improving efficiency. It enables the automation of tasks such as production planning, scheduling, inventory management, and order processing, minimizing errors and maximizing productivity.

- Seamless Integration: Manufacturing ERP software seamlessly integrates various departments and functions within the organization. It facilitates smooth communication and data sharing between departments, eliminating information silos and promoting collaboration. This integration enables efficient coordination between production, procurement, inventory, finance, and other teams, resulting in streamlined operations.

- Real-time Insights and Reporting: ERP software provides real-time insights and reporting capabilities, empowering decision-makers with accurate and timely information. It generates comprehensive reports, dashboards, and analytics that offer valuable insights into key performance indicators, production metrics, inventory levels, financial data, and more. This data-driven approach enables informed decision-making and strategic planning.

- Supply Chain Management: Manufacturing ERP software solution encompasses supply chain management functionalities, enabling manufacturers to effectively manage their supply chain activities. It assists in supplier management, demand forecasting, procurement, and logistics management, ensuring the availability of raw materials and timely delivery of finished products.

- Quality Control and Assurance: ERP software includes modules for quality control and assurance, helping manufacturers maintain consistent product quality. It enables the implementation of quality control processes, tracks quality metrics, manages inspections, and ensures adherence to quality standards, thereby reducing defects and enhancing customer satisfaction.

- Regulatory Compliance: Manufacturing ERP software solutions incorporate features to ensure compliance with industry regulations and standards. It helps manufacturers track and adhere to various compliance requirements, such as safety regulations, environmental standards, and product certifications. This ensures that manufacturing operations meet legal obligations and regulatory guidelines.

- Scalability and Customization: ERP software solutions are designed to accommodate the unique needs of manufacturing companies. They offer scalability to support business growth and can be customized to align with specific manufacturing processes, workflows, and industry requirements. This flexibility allows manufacturers to adapt the software to their evolving needs and changing business dynamics.

Overall, Manufacturing ERP software solutions work by integrating, automating, and optimizing manufacturing processes, enabling efficient resource management, data-driven decision-making, improved productivity, and enhanced customer satisfaction. By leveraging the capabilities of ERP software, manufacturing companies can streamline operations, increase profitability, and stay competitive in a rapidly evolving industry.

Also Read – ERP Software for Construction

Why is Manufacturing ERP Important for Your Business?

Manufacturing ERP is vital for businesses due to its ability to streamline operations, improve productivity, and enhance decision-making. By integrating and automating processes, manufacturers can eliminate redundant tasks, reduce errors, gain better visibility into operations, and achieve cost savings. ERP software also enables companies to adapt to changing market dynamics, stay competitive, and meet customer demands effectively.

What is the Difference Between Other ERP Software’s and eresource Manufacturing ERP?

eresource Manufacturing ERP software stands out from other ERP software solutions in several ways. Here are some key differences between eresource Manufacturing ERP software and other ERP software:

- Industry-Specific Focus: eresource Manufacturing ERP software is specifically designed to cater to the unique requirements of the manufacturing industry. It offers industry-specific features, modules, and functionalities tailored to address the specific needs of manufacturers. This industry focus ensures that eresource Manufacturing ERP software aligns closely with manufacturing processes, workflows, and best practices, providing a more comprehensive and effective solution.

- Deep Manufacturing Functionality: eresource Manufacturing ERP software offers a wide range of manufacturing-specific functionalities that are essential for efficient production operations. It includes modules such as production planning and scheduling, shop floor control, bill of materials (BOM), material requirement planning (MRP), quality control, and plant maintenance. These functionalities are designed to streamline manufacturing processes, optimize resource utilization, and enhance overall operational efficiency.

- Scalability and Customization: eresource Manufacturing ERP software is highly scalable and customizable to meet the evolving needs of manufacturing companies. It can accommodate businesses of various sizes, from small and medium-sized enterprises (SMEs) to large enterprises. Additionally, eresource Manufacturing ERP software can be tailored to align with specific manufacturing processes, workflows, and industry requirements, providing a more personalized and adaptable solution.

- Integration Capabilities: eresource Manufacturing ERP software offers seamless integration with various systems and applications within the manufacturing ecosystem. It can integrate with shop floor equipment, Internet of Things (IoT) devices, warehouse management systems (WMS), customer relationship management (CRM) software, and other third-party applications. This integration ensures a smooth flow of data, improved collaboration, and enhanced visibility across different departments and functions.

- Ease of Use and User Experience: eresource Manufacturing ERP software is known for its user-friendly interface and intuitive design. It is developed with a focus on usability, ensuring that manufacturing professionals can easily navigate the system and perform their tasks efficiently. The software’s user-friendly nature minimizes the learning curve and allows users to quickly adapt to the system, resulting in higher user adoption rates and increased productivity.

- Dedicated Support and Training: eresource offers dedicated support and training services to assist manufacturing companies throughout the implementation and usage of their ERP software. The eresource team provides comprehensive training programs, user manuals, and technical support to ensure that users can effectively utilize the software and maximize its benefits. This commitment to customer support sets eresource Manufacturing ERP software apart from other ERP solutions.

Also Read – ERP Software for Automotive Industry

Top 11 Manufacturing ERP Software Systems in 2023:

- eresource Manufacturing ERP

- SAP S/4HANA

- Oracle NetSuite

- Microsoft Dynamics 365 for Finance and Operations

- Infor CloudSuite Industrial (SyteLine)

- Epicor ERP

- Plex Manufacturing Cloud

- IQMS Manufacturing ERP

- Sage X3

- IFS Applications

- Syspro

Embrace the Power of eresource Manufacturing ERP Software

eresource Manufacturing ERP is a comprehensive software solution specifically designed for the manufacturing industry. With its robust features and modules, eresource helps manufacturers streamline their operations, improve productivity, enhance inventory management, and gain a competitive edge in the market. To get started with eresource Manufacturing ERP, visit their official website and explore the implementation options and features available.

Manufacturing ERP software plays a crucial role in helping manufacturers overcome industry challenges, improve efficiency, and achieve sustainable growth. By integrating and optimizing key business processes, manufacturers can enhance their competitiveness, adapt to market changes, and meet customer expectations. Implementing a suitable ERP solution like eresource Manufacturing ERP can revolutionize manufacturing operations and pave the way for success in the ever-evolving manufacturing industry.

Also Read – ERP Software In Mumbai