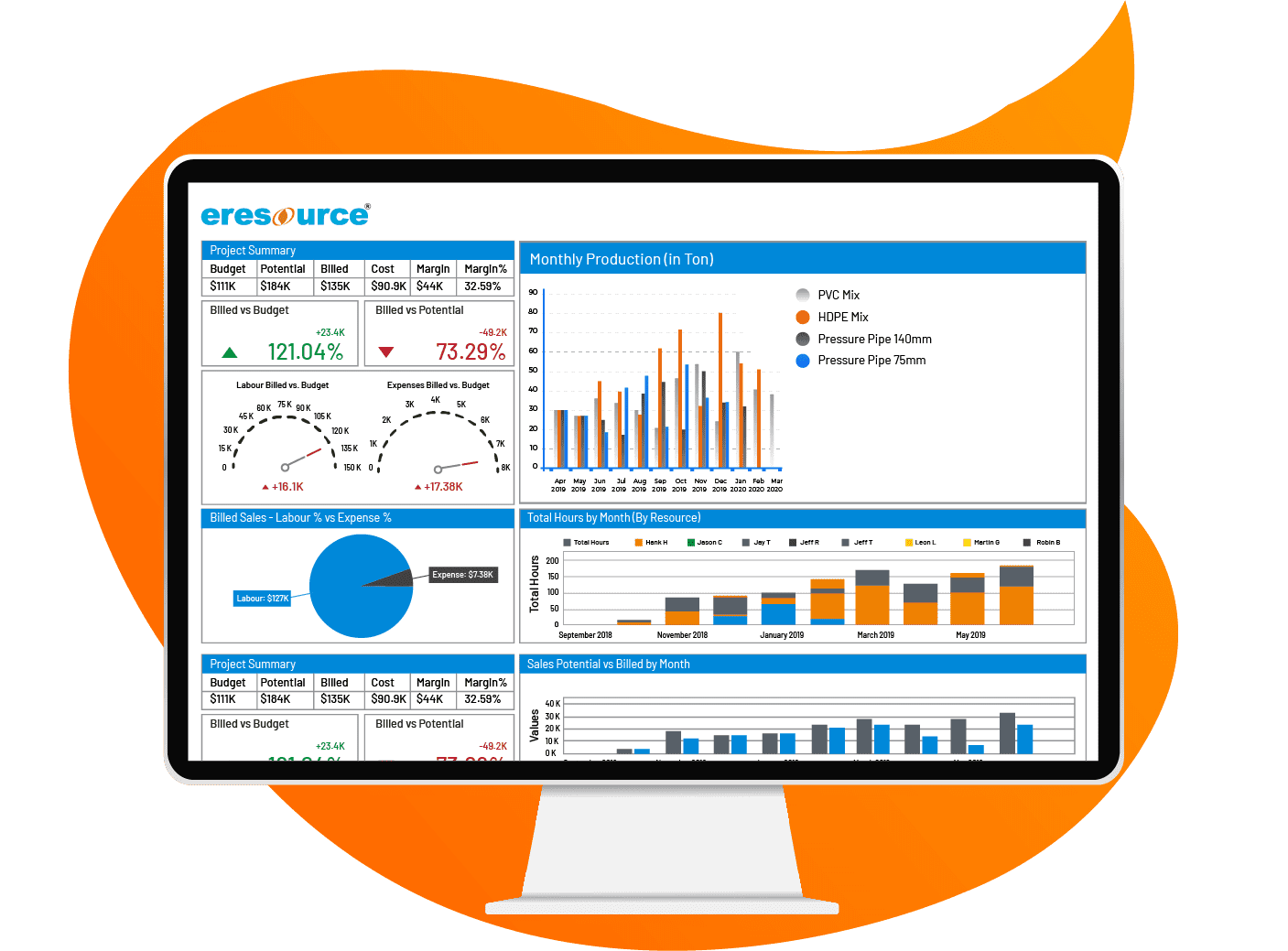

eresource Xcel ERP Software for Discrete Manufacturing would help organizations achieve higher operational efficiency and improved delivery through enhanced quality and engineering change management via its end-to-end business process integration which enables responsive manufacturing with global visibility. An Integrated Planning and Shop Floor Production Function with sales orders, inventory, purchasing, accounting, and financial reporting play an important role to provide real-time coordination across all verti... Read More

eresource ERP’s financial accounting provides company-wide integration that is essential to strategic decision making. The financial accounting module in eresource ERP gives you the ability to centrally track financial accounting data within a single framework, of multiple companies, multiple branches and chart of accounts

Stores Module in eresource ERP provides a powerful and flexible set of features to help you manage and report your inventory information. eresource Inventory Management facilitates processes of maintaining the appropriate levle of stock in a warehouse.

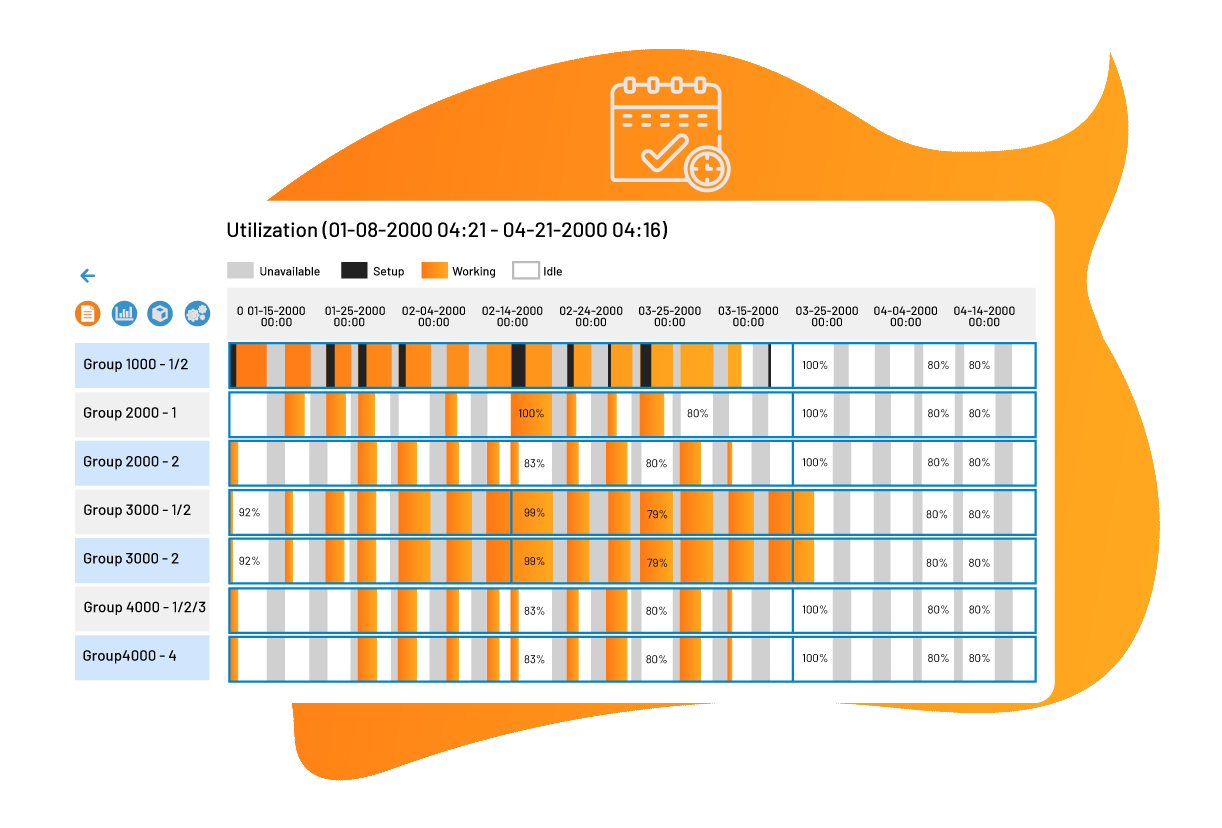

Master Planning Scheduling (MPS) provides a master plan for what you need to produce, how much to produce, and when to produce it, based upon one’s supply and demand. Eresource MPS module provides much needed information to plan and control the manufacturing operation. The application ties overall business planning and forecasting to detail operations through the Master Production Schedule.

This intelligently integrated modules of eresource Xcel ERP for Discrete Manufacturing helps organizations to manage consumption of material effectively. Customer Relation Management module in the system help the management to interact with customers directly which can reflects the market trends. The system also makes it easier for vendor interactions and dealings that helps supply chain for any components or material information in the shortest possible time. Equipped with the complete supply status you are in a better position to analyze current and potential situations and generate accurate predictions on production and supply status for customer.

eresource Xcel – logically developed ERP system for Discrete Manufacturing

The majority of operational and back-office tasks for manufacturing businesses that create unique or separately packaged goods are managed by discrete ERP software. Accounting, sales, purchasing, inventory management, and other associated procedures are all planned, managed, and tracked using discrete ERP systems.

Manufacturers can determine what needs to be produced based on demand, what raw materials are needed for production, and how to develop and carry out production plans by using discrete ERP software. Discrete ERP technologies also assist producers in ensuring that goods are delivered to clients in a high-quality manner.

Considering the above factors regarding the discrete manufacturing segment, eresource has developed its exclusive ERP system eresource Xcel for discrete manufacturing companies.

eresource Xcel discrete ERP software is essential for the production team because of its wide range of applications. It may be utilized by all divisions within a manufacturing organization. Accounting professionals handling financial transactions, purchasing managers handling fulfillment, and warehouse managers overseeing raw material and finished goods inventories should all use separate ERP platforms for best outcomes.

Web-based cloud-deployed ERP system

eresource Xcel ERP for Discrete Manufacturing can be implemented as a package containing several modules on a cloud-based model or on the premises model. A core package and subscription model can also be purchased separately as per each company requirement. The system has interface with other enterprise software, including supply chain suites, PLM programs, HR management suites, and CRM all-in-one programs.

There are over 3000 Manufacturing companies using eresource Xcel ERP and that includes, Make To Order, Make to Stock, Engineer to Order, Assemble to Order and Mix Mode Manufacturing companies. We also exclusive ERP Software for Process Manufacturing or batch manufacturing practice, We call that product as “BPro ERP”.

Although manufacturers have been using ERP software for decades, the advancement of technology, shifts in consumer behavior, and changes in the economy are causing discrete businesses to reevaluate their goals. As a result, companies use discrete manufacturing ERP systems like eresource Xcel to handle both established and novel business problems.

One source of veracity

Manufacturers are able to manage a variety of information types, including customer data, inventory, production, and sales or purchase transactions, more effectively when they have a single source of truth in an ERP database. Additionally, it makes finding information on almost everything kept in the ERP database easier, which makes reporting and analytics easier as well. Spreadsheet use is typically decreased or eliminated when utilizing this integrated ERP system, which also replaces a number of other tools, point solutions, and add-ons. Manufacturers can prevent errors resulting from duplicate data entry and issues caused by a lack of interaction across disparate solutions by implementing an integrated ERP.

Replacing outdated or inadequate technology

When factories outgrow their existing systems and are unable to manage complicated processes, it is especially critical to replace outdated technologies. Furthermore, production management tools are typically absent from accounting software. For expanding manufacturers, the functionality related to purchasing, sales, and inventory is sometimes too simplistic. Although building one’s own system might have been a smart idea in the past, firms who have done so are now finding it difficult to stay up to date with new developments in technology.

Enhanced output

Employees that are more productive have more time to concentrate on important tasks rather than labor-intensive tasks like data input. This is especially crucial for workers engaged in manufacturing processes, as worker productivity directly affects production output. Enhancing productivity can also boost motivation, which will raise worker efficiency.

The fact that users make mistakes more frequently when they lack the necessary tools or simple access to the information to complete their tasks is another significant element that has a negative impact on productivity. Manufacturers can now implement eresource Xcel ERP application that provide all capabilities they require, including a single data repository, to break free from this vicious cycle.

Control of production in several locations

Nowadays, especially for small firms, managing production across different locations can be a significant burden. Because of acquisitions, mergers, and uneven IT strategies, many manufacturers have many locations where they use different solutions. Manufacturers can enhance information exchange and teamwork across all of their teams, no matter where they are located, with an integrated ERP system that can be accessed anywhere. Manufacturers can also enhance the administration of equipment or resources by using a discrete ERP system eresource Xcel that can be utilized by several locations.

Lowering expenses and increasing profitability

Even though an ERP system is a significant investment, it can help firms achieve better return on investment over time in two ways: by lowering costs and raising profitability. The company’s overall profitability rises when worker productivity rises and production expenses fall. eresource Xcel ERP helps manufacturers cut back on back office expenses by decreasing employee error rates and the amount of time spent on routinely laborious operations.

Assistance for the company’s future growth

Manufacturers should ensure that ERP will be in use for a minimum of five to ten years, as choosing and implementing the system is an expensive and disruptive procedure. This implies that as businesses expand, they must choose an ERP solution that can change to meet their evolving needs. Discrete manufacturers should be able to start with the features that are most important to them and add new capabilities as needed by the business, thanks to eresource Xcel ERP solution that is suitably flexible.

Adjusting to shifts in the market

Because manufacturing processes are so intricate, it takes a great deal of time and energy for manufacturers to adjust to a changing market. For instance, manufacturers must provide new products when one or more of their current offerings become outdated. In this process, new designs are made, suppliers of new components are located, potential clients are estimated, and manufacturing line setup is reviewed. eresource Xcel discrete manufacturing ERP software readily facilitates all of these tasks. Xcel ERP software system may track operations and expenses, deliver pertinent information rapidly, and offer insights into the efficacy of corporate actions.

Using new technology

The advantages of new technology, such as cloud or mobile-only deployments, come with software that adapts to the ever changing technological landscape. For example, manufacturers typically cannot afford to construct and operate data centers to store their data on the cloud, with the exception of very large businesses. Manufacturers might delegate some of their obligations for data security and privacy to the cloud. Manufacturers who use cloud ERP like eresource Xcel don’t have to worry about upgrades or data backups because the ERP provider handles these services.

Better ties with suppliers

It is imperative for discrete manufacturers to enhance their connections with suppliers. They must purchase all of the parts, raw materials, and components required for production because they are typically unable to make them all. The biggest issue that manufacturers have when collaborating with suppliers is that they have no control over the final product’s quality. The globalization of the economy, which enables suppliers to manufacture anywhere in the world but can also lead to logistical issues, is another significant challenge. Because of this, manufacturers require an ERP system in order to keep track of their suppliers’ past performance, assess their performance, and select the best provider for their needs. Thus, ERP can assist firms in streamlining their supply chains, which enhances the consumer experience.

Adherence to quality guidelines and standards

Not only is quality required by law, but it also gives you a competitive edge. Manufacturers who go above and above what the law requires in terms of quality management are the most successful. Manufacturers must also abide by contractual requirements pertaining to quality. Although each of them can significantly affect the client experience, they are all too complicated to handle with separate systems or simple software. Manufacturers can only establish, implement, and oversee quality management programs at every stage of the product lifecycle—from design to end of life—with the use of eresource Xcel ERP solution.

These are accounting solution with inventory and sales order processing. These solution are good for small Trading companies. But if you are in Manufacturing, contracting or service industry, you would need a exclusive ERP product which is designed exclusively for your business. For example, Manufacturing ERP comprises of very comprehensive Production and Shop floor operation, capacity and Demand management, Planning and Material management, Supply Chain Management, Customer Relationship, Fixed Asset and Accounts and Finance Management. If you need visibility of all strategic information across all your departments and divisions on-time so that you can take decision faster, yes, then, you need to switch over.

eresource is the only ERP system that is 100% scalable, flexible and adapts to different business dynamics with any programming efforts. It is ZERO coding ERP product. The entire ERP is evolved out our in-house framework. Because there is no programing the deployment becomes extremely fast. Even after the deployment if the customer may require any changes, the lead time for any change is not more then an hour. I cannot miss to tell you, Migration of data is possible in just few clicks. Maximum time to Implement any ERP is 25 working days.

There is no customization in eresource ERP. Any changes/alteration is 100% configurable.

A integrated web-based ERP software provides a degree of interoperability that was difficult and expensive to achieve with standalone, custom-built systems. eresource’s web-based ERP serves many industries and numerous functional areas in an integrated fashion and automate operations from supply chain management, inventory control, manufacturing scheduling and production, sales support, customer relationship management, financial and cost accounting, human resources and almost any other data-oriented management process.

With an ERP system like eresource, business operations have become much easier. For example, when a salesperson enters an order in the field, the transaction can immediately flow through to other functional areas both within and external to the firm. The order might trigger an immediate change in production plans, inventory stock levels or employees’ schedules, or lead to the automated generation of invoices and credit evaluations for the customer and purchase orders from suppliers.

Every growing organization must realize that ERP systems have become the most significant IT investment for most companies in their capital budgeting.

A integrated web-based ERP software provides a degree of interoperability that was difficult and expensive to achieve with standalone, custom-built systems. eresource’s web-based ERP serves many industries and numerous functional areas in an integrated fashion and automate operations from supply chain management, inventory control, manufacturing scheduling and production, sales support, customer relationship management, financial and cost accounting, human resources and almost any other data-oriented management process.

With an ERP system like eresource, business operations have become much easier. For example, when a salesperson enters an order in the field, the transaction can immediately flow through to other functional areas both within and external to the firm. The order might trigger an immediate change in production plans, inventory stock levels or employees’ schedules, or lead to the automated generation of invoices and credit evaluations for the customer and purchase orders from suppliers.

Every growing organization must realize that ERP systems have become the most significant IT investment for most companies in their capital budgeting.

As far as any business is concerned, customer demand is by far the most influential factor. Manufacturing industry is one of the businesses that strive to make a nation grow with its contribution to the national economy. And a country that gives priority to its manufacturing sector could achieve success in its mission to bring the country into the mainstream of world business. India’s new initiative in this phase, ‘Made in India’, is moving in the right direction with many overseas companies are finding our nation as a fertile soil to manufacture their goods indigenously.

eresource, a purely indigenous Manufacturing ERP software, is contributing largely into the growth of manufacturing business by providing one of the excellent technology. When the automation becomes way of life no companies can keep away from this technological advantage. Understanding the need of every industry, eresource has come out with industry specific ERP system for every industry verticals and ‘eresource Xcel’ is an exclusive ERP system developed for manufacturing industry. eresource Xcel, a viable ERP system that has been integrated with all essential modules for manufacturing industry.

• eresouce Xcel is an enterprising solution for manufacturing businesses through a variety of modules. Following are some of its modules and its functions:

• CRM module: Maintains a data of customer history.

• BOM module: Helps in maintaining product requirement details

• MPS module: Generates a detailed list of orders and required purchases

• Enterprise resource planning: Inventory management for the business

• Quality control module: Provides support from start till delivery.

• Job work management: Creates an easier way to manage outsourced work

• Finance resource management: accumulates all the financial information of all functional departments

• Production management: streamlines the manufacturing processes.

• Human Capital Management module: Manages the human resources of the business

Following are some of the prime advantages of eresource Xcel,