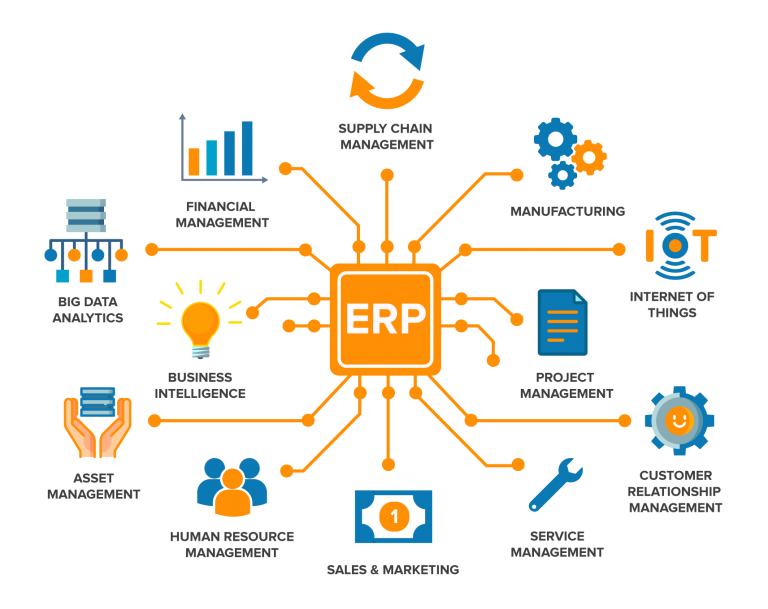

With the emergence of IoT technology and the Industry 4.0 version, the manufacturing sector is undergoing a massive digital transformation. From procurement and production to payroll management, technology-driven solutions are transforming each function necessary for the seamless working of manufacturing companies. One such technology-driven solution is ERP for manufacturing industry.

Today, you can get your hands on many ERP applications explicitly designed for the manufacturing industry. However, not all these applications are the same and ideal for your manufacturing company.

Eresource Xcel offers high-performing ERP software that can help manufacturers transform unstructured production processes into automated routine transactions. Moreover, the eresource ERP is equipped with several exceptional features, helping manufacturing companies reduce costs in three primary categories, including inventory, manufacturing operations, and administrative costs.

Let’s learn more about the features of eresource Xcel manufacturing ERP software.

- Manufacturing Modules

Manufacturing modules are the critical component of eresource Xcel manufacturing ERP software. Starting from materials requirement planning (MRP), ERP software has evolved and now includes various manufacturing-related modules like inventory management, production management, and manufacturing execution systems.

With manufacturing modules, manufacturers can plan their production schedule, ensure optimal allocation of resources and raw materials, and track output against forecasts. Moreover, manufacturing ERP modules provide a real-time view of manufacturing operations by collecting data about in-progress and finished products.

- Inventory Management

Every manufacturing organization needs a healthy inventory stock to produce demanded goods in time. Eresource Xcel manufacturing ERP software provides manufacturers with complete control over the inventory stock and raw materials available in the company. The software provides manufacturers real-time visibility into inventory levels and automates the stock ordering process.

- Production Planning

With Eresource Xcel ERP software for manufacturing units, you can plan and schedule production based on demand forecasts, raw material availability, and production capacity constraints. Additionally, you can get real-time updates on production progress and capacity utilization.

- Automated Processes

ERP-driven automation allows manufacturers to automate their manual processes, resulting in reduced human efforts and errors. The technologically advanced software helps manufacturing organizations automate various processes, including procurements, sales invoicing, HR functions, and more.

- Quality Control

Poor product quality can be detrimental to your manufacturing company, leading to huge losses. With quality control ERP module, manufacturers can ensure their finished products meet relevant quality standards and regulations.

Eresource Xcel manufacturing ERP software can help manufacturing companies track and manage quality control throughout the production process, from incoming raw materials to producing finished products. In addition, the platform provides real-time quality control data to help identify any issues with finished products and correct them on time.

Also Read – ERP online demo

- Supply Chain and Distribution Management

Inefficient supply chains and distribution can result in delayed production and deliveries of finished goods. The supply chain and distribution management feature of eresource Xcel manufacturing ERP software can help track the real-time movement of goods across multiple supply chain channels. These channels include suppliers, manufacturers, distributors, retailers, and end customers.

Moreover, the software can provide real-time updates on supplier or distributor performance, inventory levels, and order status for timely production and deliveries. Manufacturers can also use the ERP software to manage products or materials for replacements or refunds.

- Accounting and Finance

Eresource Xcel ERP software provides access to the accounting and finance modules to help manufacturers monitor their financial transactions and accounts, allowing businesses to improve their profits and reduce expenses. Through integration, accounting and finance managers can allocate the right budget to procure raw materials, labor, and transportation. Moreover, real-time financial data related to your manufacturing unit can help you make informed decisions.

Also Read – ERP Software for Construction

- Customer Relationship Management (CRM)

Establishing strong relationships with target customers and maintaining them for a long is the key to the long-term success of your manufacturing business. Eresource Xcel manufacturing ERP platform can help manufacturers manage customer relationships by providing real-time updates on order status, product availability, and shipping information.

Furthermore, you can use the ERP software to track customer interactions and access data to understand customer needs and preferences better.

Summing up it all

It has become imperative for manufacturing companies to digitize and automate their operations to adapt to changing business environments and gain a competitive edge. Eresource Xcel ERP for manufacturing company is a technologically advanced solution, enabling manufacturers to achieve operational agility and process efficiency.

Moreover, deploying this software can reduce your manufacturing business’ operating costs while enhancing productivity. Eresource erp is an award-winning ERP solution provider that provides the above-discussed features to streamline manufacturing operations.

Also Read – ERP Software company