One ERP. Every Industry. Global Presence. Powered by Azaalea AI

One ERP. Every Industry. Global Presence. Powered by

Total Quality Management in ERP

A comprehensive solution designed to manage all aspects of quality control and assurance in manufacturing processes.

Total Quality Management in ERP

A comprehensive solution designed to manage all aspects of quality control and assurance in manufacturing processes.

Why choose this module

Centralized quality

ecosystem

All quality checks, audits, and metrics managed under one roof.

Real-time visibility

Instant insight into inspection results, rejections, and trends.

Cause and corrective

tracking

Identify and resolve issues faster with full traceability.

Automated approvals

Reduce manual effort with rule-based inspection triggers and approvals.

Supplier and customer

quality integration

Extend quality assurance beyond production to vendors and clients.

Quality Flow

Complete quality lifecycle in one system

Define inspection plans, sampling methods, and acceptance criteria.

Capture inspection data during incoming, in-process, and final stages.

Record rejections, deviations, and non-conformance reports.

Trigger corrective and preventive actions automatically.

Track supplier performance through incoming quality stats.

Log customer complaints and link them to product batches.

Generate real-time reports on quality costs, performance, and defects.

Continuously refine processes based on insights and analytics.

Core capabilities

- Create detailed inspection templates per item or process.

- Define test parameters, sampling size, and control limits.

- Schedule routine or conditional inspections.

- Link inspection to purchase, production, or sales documents.

- Record results digitally with pass/fail criteria.

- Automatically log rejected materials or failed processes.

- Assign corrective actions and root cause owners.

- Track containment, correction, and closure steps.

- Maintain complete traceability of issues.

- Generate CAPA (Corrective and Preventive Action) reports.

- Evaluate supplier quality based on incoming inspection results.

- Maintain supplier scorecards and ratings.

- Capture vendor non-compliance and share corrective feedback.

- Schedule audits for critical vendors.

- Integrate with procurement for vendor improvement programs.

- Enforce quality gates at production stages.

- Capture test readings from shop floor or devices.

- Approve or reject lots based on tolerance limits.

- Auto-block non-compliant batches from next process.

- Integrate with production and warehouse modules.

- Log complaints linked to batch, lot, or serial number.

- Track issue resolution status and turnaround time.

- Escalate unresolved complaints automatically.

- Generate reports on recurring customer issues.

- Improve service quality using real-time insights.

- Monitor defect rates, rejection costs, and CAPA closure time.

- Compare supplier and process performance over time.

- Generate trend graphs for recurring issues.

- Access dashboards for quality KPIs.

- Enable data-driven decision making for improvement.

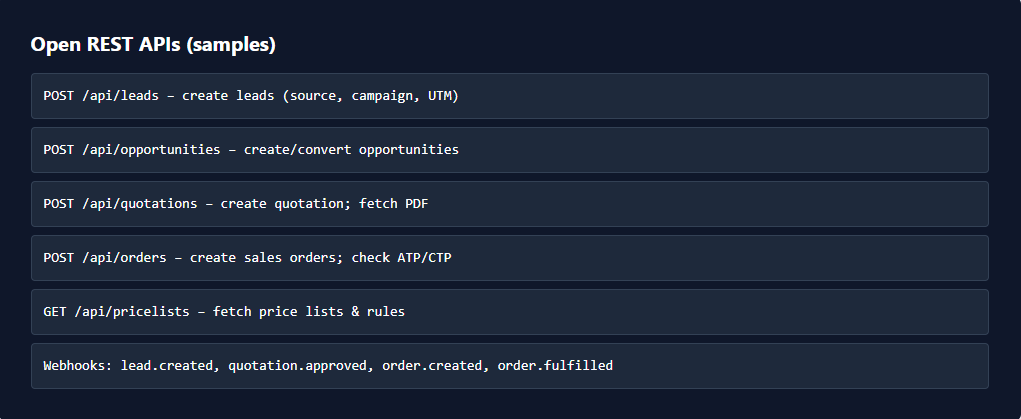

Integrations & APIs

- Quality status synced with production and warehouse.

- Auto-block defective batches from further use.

- Connect supplier audits and customer complaints seamlessly.

- Feedback loops for process improvement across modules.

Automation examples (no-code)

initiate inspection when goods are received or production ends.

automatically assign root cause owners and due dates.

notify quality heads if rejection exceeds threshold.

auto-assign service cases to responsible departments.

Role-based views

Quality Manager

View inspection results, trends, and CAPA status across all plants.

Quality Inspector

Assigned inspections, results entry, rejections, and follow-ups.

Production Supervisor

Access process quality, rework orders, and rejected batch details.

Supplier Manager

Monitor vendor quality performance and audit schedules.

Customer Service Lead

Track complaints, resolutions, and turnaround time.

Top Management

Monitor quality KPIs, costs of poor quality, and compliance reports.

KPIs to track

Incoming material rejection rate

In-process defect %

Supplier quality score

Customer complaint closure time

Cost of poor quality (COPQ)

CAPA closure rate

Frequently

Asked Questions

Get answers to common questions about Total Quality Management Module

What does the Total Quality Management module handle?

It manages all inspection, non-conformance, CAPA, and quality assurance activities within eresource ERP.

Can inspection plans be customized per product?

Yes, you can define different parameters, acceptance limits, and workflows for each item.

Does it integrate with production and inventory?

Absolutely — defective batches can be automatically blocked or routed for rework.

Is supplier and customer quality tracked too?

Yes — vendor quality and customer complaints are both managed under the same system.

Can it provide analytics and dashboards?

Yes, real-time dashboards display quality KPIs, defect rates, and performance comparisons.

Does it support no-code automation?

Yes, users can configure triggers, approvals, and alerts without technical coding.

Quality Built into Every Step

Ensure zero-defect production and complete compliance with eresource ERP’s Total Quality Management module. From inspection to improvement, your quality standards are built into every process.

Email: sales@eresourceerp.com · Website: www.eresourceerp.com