Even in the modern Internet age, some businesses still use paper-based management systems like books and registers, spreadsheet programs like Excel, and in certain circumstances, specialised stand-alone software that was either developed in-house or installed by an outsider. The aforementioned amenities will assist you to some level if your organisation is recently founded till some expansion occurs in the business process.

The administration of vast and ever expanding information data, including emails, financial transaction data, inventory data, production data, vendor data, and employee database, is the major difficulty facing businesses today. The improper management of this information data can have negative effects on a company’s bottom line. For example, incorrect invoices can result in customer payment delays or taxation issues, incorrect inventory levels can cause problems in the production area, excess inventory can lock up much-needed working capital, improper production schedules can waste labour hours, and late deliveries can lower customer satisfaction levels. All of this will eventually have an impact on how an organization’s business processes develop.

Also Read – ERP for Steel Industry

Selection of right ERP system is the key factor

One of the most frequent issues encountered throughout the ERP deployment is indecision among the decision-makers. Sometimes management-level users at lower staff levels are unable to make the best option about an ERP deployment. Ineffective training also contributes to inappropriate or nonexistent use of an ERP project. Finding the right ERP and using its training techniques are crucial for the success of an ERP project. With its effective deployment strategy and top-notch user training sessions, eresource ERP had left its mark on the industry. An organisation is on the right track towards a successful business solution when it decides to use a web-based ERP solution.

It is also true that, in the ordinary course, some businesses perceive the ERP differently because they view it as a magic mantra. There may be a variety of causes. Everyone should be aware that there are no clear-cut factors that can be identified for the success or failure of an ERP deployment. There could be a lot of reasons why an ERP setup fails. As a result, businesses need to properly reevaluate any planned ERP systems. If you conducted the evaluation properly, we are confident that there won’t be many factors that could lead to the failure of your ERP deployment.

Also Read – Best cloud manufacturing ERP for MSME in India

eresource ERP enables organisational standardisation

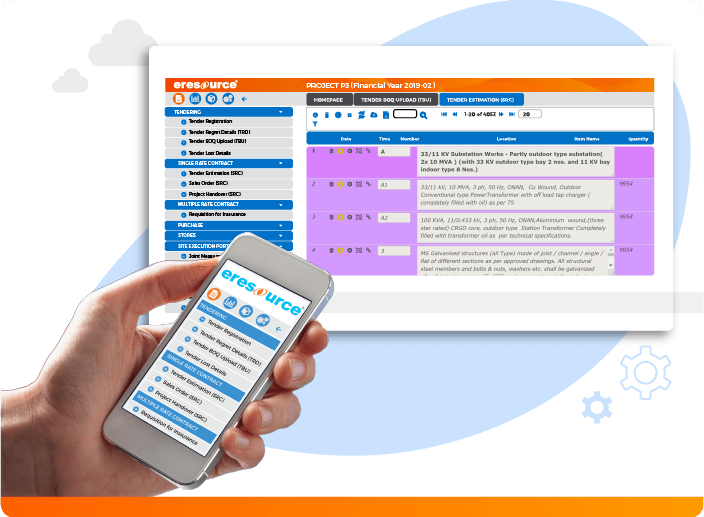

Numerous case studies on customers of eresource have shown that everyone has profited financially from increased efficiencies. Tasks like the creation of customer quotations, multi-tax bills, account reconciliation, etc., were accelerated thanks to the automation capabilities of the eresource ERP System.

Organisational standardisation across sites is made possible by our ERP systems. It is possible to align those areas with subpar processes with other, more effective ones as a result.

Additionally, the business can provide the outside world with a single image. When a company manages various branches or plants, the globe might be supplied with a single common view that presents the greatest picture, as opposed to obtaining various papers.

Do not delay in implementing eresource ERP system in your organization because this is one of the most reliable business applications that could assist you in achieving your business goals.

Also Read – Benefits of ERP in Production Planning