One ERP. Every Industry. Global Presence. Powered by Azaalea AI

One ERP. Every Industry. Global Presence. Powered by

Maintenance Module

From preventive to corrective maintenance—manage all your equipment servicing in one platform.

Maintenance Module

From preventive to corrective maintenance—manage all your equipment servicing in one platform.

Why teams choose this module

Configured without

code

Configure workflows, schedules, and alerts easily, no heavy IT intervention.

Unified maintenance

lifecycle

From service request to resolution, the full cycle is managed in one system.

Real-time visibility

Monitor status, downtime, service history and cost in one dashboard.

Automated scheduling

& alerts

Prevent breakdowns with automated task generation and notifications.

Integration with

modules

Maintenance data flows into asset cost tracking and financial ledgers.

Maintenance Flow

Complete maintenance lifecycle in one system

Log service requests from equipment, machinery or assets.

Automatically schedule preventive tasks based on usage or calendar.

Create work orders, assign technicians and resources.

Perform inspection, record findings, update status and costs.

Track spare parts usage and service expenditure.

Report on downtime, corrective work and root cause analysis.

Close work orders and update asset history.

Post maintenance cost to finance and assess return on maintenance investment.

Core capabilities

- Multi-level BOMs with components, sub-assemblies and variants.

- Convert requests into work orders with approvals.

- Prioritize tasks by urgency, asset criticality or risk.

- Assign technicians, tools and parts.

- Track status, time taken and completion metrics.

- Schedule routines based on time, usage or meters.

- Trigger alerts when maintenance windows approach.

- Integrate usage data or IoT readings for predictive alerts.

- Auto-generate work orders when thresholds hit.

- Log service history for future trend analysis.

- Track inventory of spare parts tied to equipment.

- Allocate parts to work orders, monitor consumption.

- Manage vendor contracts for parts/services.

- Track tool usage, calibration schedules.

- Control cost centres for parts and labour.

- Monitor equipment uptime, breakdown times and repair rates.

- Analyse downtime by root cause or asset group.

- Track asset utilisation vs capacity.

- Report on mean time between failures (MTBF) and mean time to repair (MTTR).

- Identify under-performing assets and recommend action.

- Link maintenance costs to GL, cost centres or projects.

- Auto-post labour, material and overhead costs.

- Provide variance reports and budget tracking.

- Capitalize overhaul costs when required.

- Generate audit-ready cost summaries.

- Record inspections, safety checks and audit compliance.

- Track work permits, lock-out/tag-out schedules.

- Maintain documents & certifications per asset.

- Trigger alerts for certifications or regulatory expiry.

- Provide dashboards for safety and compliance KPIs.

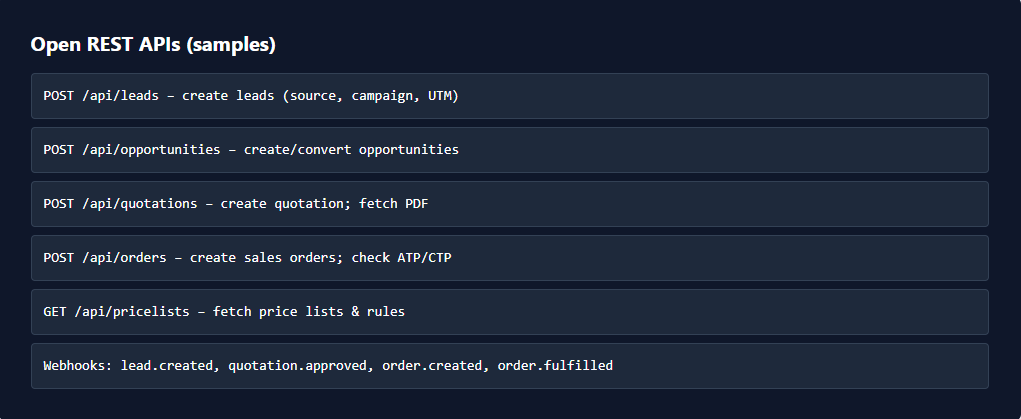

Integrations & APIs

- Maintenance status and cost feed into asset value and depreciation.

- Work-order cost flows to finance for accrual and reporting.

- Connect sensors for equipment health, vibrations, temperature.

- Real-time fault alerts from machines via API.

Automation examples (no-code)

trigger when a sensor detects % usage or timer threshold.

notify managers if preventive tasks are overdue.

when spare parts fall below reorder, auto-create requisition.

escalate if downtime exceeds defined threshold.

Role-based views

Maintenance Manager

View all open/overdue work orders, resource load, asset health.

Technician

My assigned tasks, spare parts, equipment history, completion input.

Inventory Clerk

My parts requests, stock status, reorder alerts, issue tracking.

Finance Controller

Maintenance cost summary, asset cost integration, budget variances.

Compliance Officer

Safety checks, audit log, certification status, inspection schedule.

Operations Director

High-level dashboard: uptime, MTTR, asset utilisation, maintenance ROI.

KPIs to track

Asset uptime %

Mean Time To Repair (MTTR)

Mean Time Between Failures (MTBF)

Maintenance cost per asset

Preventive vs corrective maintenance ratio

Scheduled task completion %

What does the Maintenance Module in eresource ERP cover?

It covers service request management, preventive scheduling, work orders, parts and cost tracking, all integrated with assets and finance.

Can it support predictive maintenance using sensor data?

Yes — the module supports IoT integration for usage or health-based triggers.

Does it integrate with finance and asset modules?

Yes — maintenance costs and work orders link into asset valuation and financial reporting.

Can we configure workflows without coding?

Yes — workflows for approvals, alerts and task generation are configurable.

Is it suitable for multiple plants and locations?

Yes — supports assets, users, and tasks across locations, departments and shifts.

Are there dashboards and analytics for maintenance performance?

Absolutely — real-time reports on asset health, costs and downtime are included.

Produce with Precision. Deliver with Confidence.

With eresource ERP’s Production Module, you gain full manufacturing control—from planning to production to delivery.

Email: sales@eresourceerp.com · Website: www.eresourceerp.com