One ERP. Every Industry. Global Presence. Powered by Azaalea AI

One ERP. Every Industry. Global Presence. Powered by

Production Module

From planning to finished goods – manage your entire manufacturing cycle in one integrated system.

Production Module

From planning to finished goods – manage your entire manufacturing cycle in one integrated system.

Why teams choose this module

Configured without

code

Set up BOMs, routing, workflows, and dashboards without heavy IT involvement.

Unified plan-to-

produce flow

From master production schedule through to output and inventory—all in one platform.

Real-time visibility

Track work orders, machine usage and progress across lines and locations.

Automated resource

allocation

Automatically assign machines, operators and materials based on availability.

Quality & cost control

built-in

QC checks, wastage tracking, and cost variance monitoring embedded in production process.

Production Flow (Plan → Produce → Deliver)

Complete manufacturing lifecycle in one system

Define product structures and BOMs (Bill of Materials)

Create master production schedule (MPS) and allocate capacity

Generate production work orders and assign execution resources

Execute on shop-floor: record job card, consumption, yield

Perform goods receipt or finished goods transfer

Run quality inspections and accept/reject batches

Update inventory and cost ledgers

Analyse output, scrap, efficiency and variance

Core capabilities

- Multi-level BOMs with components, sub-assemblies and variants.

- Version control and revision tracking.

- Routing definitions for operations, machines and labor.

- Link BOMs to sales orders and production orders.

- Cost roll-up and variance tracking.

- Forecast-led production planning.

- Capacity availability and allocation by line/shift.

- Demand vs supply balancing across plants.

- Schedule drills, rescheduling and Gantt views.

- Integration with sales orders and inventory signals.

- Create and manage production work orders.

- Job card tracking: operations, machine, labor.

- Monitor progress, update statuses and log exceptions.

- Support for by-product and waste tracking.

- Multi-location and multi-site production tracking.

- Define QC parameters and testing at various stages.

- In-process and final inspection workflows.

- Lot/serial tracking and genealogy.

- Non-conformance, hold & reject management.

- Traceability reports for audits and compliance.

- Track material consumption against BOM and work orders.

- Machine and tool usage, die/mould tracking.

- Wastage and scrap recording and cost adjustment.

- Resource optimization across lines and shifts.

- Inventory linkage for raw materials, semi-finished goods and finished goods.

- Dashboards for production efficiency, downtime, yield.

- Monitor machine utilization, OEE (overall equipment efficiency).

- Cost variance, scrap rate and process improvement metrics.

- Predictive insights via historical data and AI/ML (optional).

- Customisable reports and scheduled alerts.

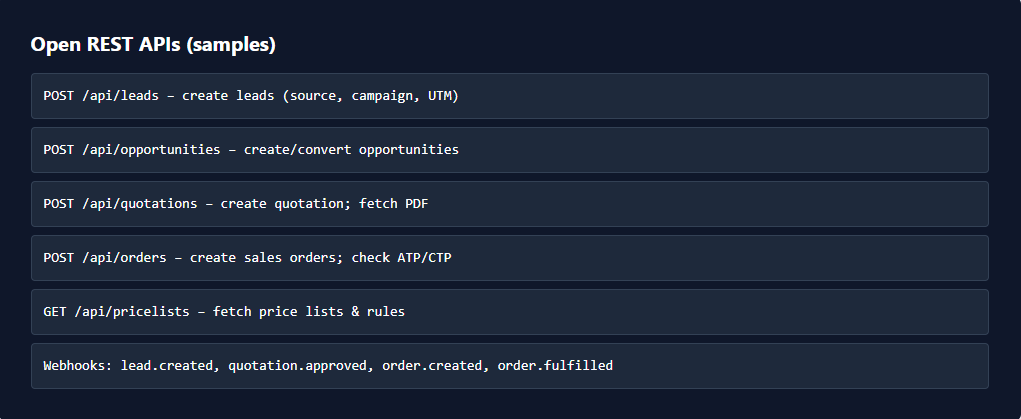

Integrations & APIs

- Real-time integration with inventory, purchase, sales and finance.

- Production order commitments, etc flow into finance for cost control.

- APIs to integrate machine sensors for runtime, downtime and efficiency data.

- Live feed from shop-floor to ERP dashboards and analytics.

Automation examples (no-code)

trigger orders when sales order or MPS demand arises.

send notification when machine downtime exceeds threshold.

auto create requisition when BOM component inventory drops.

auto route non-conformance reports and corrective actions.

Role-based views

Production Manager

My scheduled work orders, line performance, bottlenecks, scrap summary.

Shop-floor Supervisor

My job cards, machine load, crew attendance, material issues.

Quality Engineer

My inspection tasks, failed lots, non-conformance tracking, approvals.

Inventory/Stores Clerk

My material requisitions, consumption reports, deviation alerts.

Finance Manager

My production costs, variances, WIP valuations, scrap impact.

Operations Director

Dashboard: OEE, throughput, downtime, on-time-delivery.

KPIs to track

Work order cycle time (release → completion)

Overall Equipment Efficiency (OEE)

Scrap/waste percentage

On-time delivery of finished goods

Production cost variance (budget vs actual)

Yield rate (good units / total units)

What does the Production Module cover?

It covers the full manufacturing process: BOM, planning, orders, shop-floor execution, quality, inventory and cost management.

Can it support multiple plants or locations?

Yes — production across multiple locations, lines, and plants is supported.

Does it provide traceability and quality control?

Yes — full traceability via lot/serial, and integrated quality workflows.

Can it integrate with IoT devices and sensors?

Yes — machine-monitoring, live shop-floor data and predictive insights are possible.

Is the module scalable for different manufacturing types (MTO, MTS, ETO)?

Yes — supports make-to-order, make-to-stock, engineer-to-order and batch manufacturing.

How quickly can this be implemented?

Implementation time varies based on scope and custom-config, but the low-code/no-code framework of eresource helps accelerate deployment.

Produce with Precision. Deliver with Confidence.

With eresource ERP’s Production Module, you gain full manufacturing control—from planning to production to delivery.

Email: sales@eresourceerp.com · Website: www.eresourceerp.com