One ERP. Every Industry. Global Presence. Powered by Azaalea AI

One ERP. Every Industry. Global Presence. Powered by

ERP Software for Steel Industry

Industry-specific eresource Xcel ERP system for Steel manufacturing process

ERP Software for Steel Industry

Industry-specific eresource Xcel ERP system for Steel manufacturing process

About the Industry

Steel manufacturing is a complex, asset-intensive industry involving large-scale production processes, continuous operations, strict quality standards, and heavy material movement. Manufacturers produce steel coils, sheets, pipes, tubes, structural sections, and customized fabricated products for construction, automotive, oil & gas, and industrial applications.

Production involves multiple stages such as billet casting, reheating, rolling, slitting, forming, welding, annealing, galvanizing, coating, finishing, and dispatch. Managing raw material procurement, furnace operations, rolling mill scheduling, yield control, scrap recovery, and quality compliance is critical to profitability.

Manual tracking or disconnected systems often result in production delays, incorrect material consumption, uncontrolled scrap, poor lot traceability, and inaccurate costing.

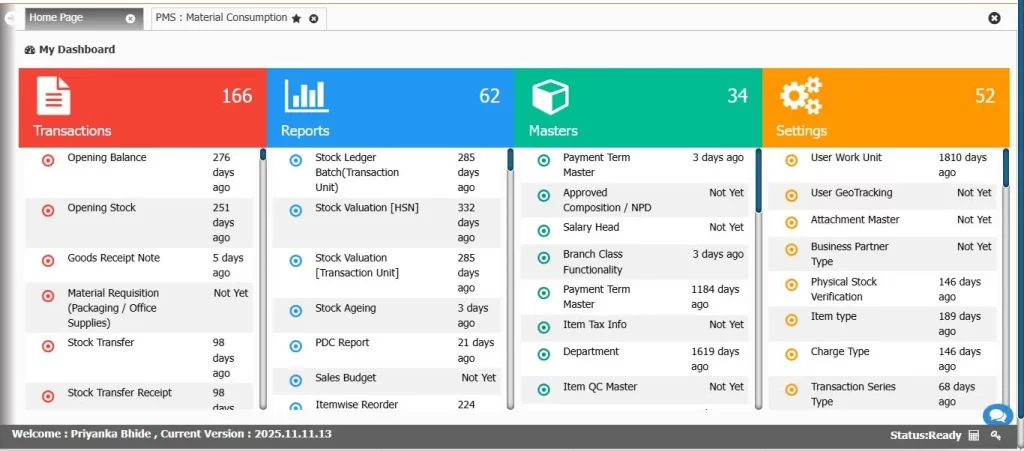

eresource Xcel ERP is purpose-built to support steel manufacturers by integrating production, material planning, job or lot manufacturing, inventory, quality, costing, and financial operations within one unified system.

The platform supports manufacturers of steel coils, sheets, pipes, tubes, rolled products, fabricated sections, and specialized steel components, providing full visibility across production, inventory, and dispatch operations.

With real-time operational intelligence and automated workflows, eresource Xcel ERP helps steel manufacturers reduce waste, improve yield, optimize plant utilization, and enhance profitability.

Why Choose eresource Xcel ERP for Steel Manufacturing?

Steel production environments operate with high-volume throughput, tight production schedules, and strict quality and traceability requirements. Traditional ERP systems often fail to capture plant-level operations or lot-based production complexities.

eresource Xcel ERP is designed to handle continuous and lot-based steel manufacturing, ensuring complete operational control.

- Key Advantages:

- Supports billet, coil, pipe, and sheet production workflows

- Tracks heat numbers, lot numbers, and production batches

- Manages rolling mill operations and pipe manufacturing lines

- Controls scrap generation and recovery processes

- Handles production planning across furnaces, mills, and forming lines

- Provides real-time production and costing insights

- Integrates procurement, production, dispatch, and finance seamlessly

With production transparency and accurate costing, steel manufacturers gain improved plant efficiency and stronger margin control.

Core Modules

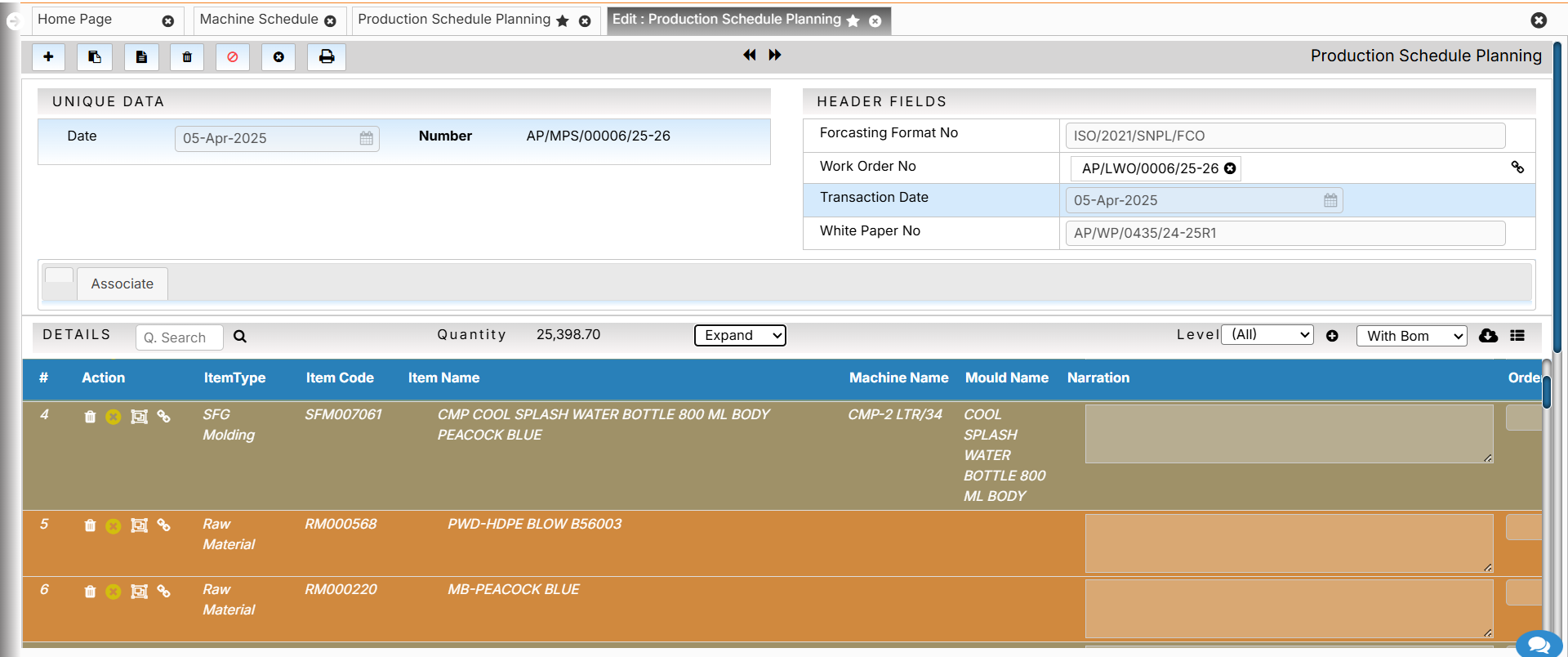

Production Scheduling

Enables efficient planning, sequencing, and allocation of production tasks to ensure optimal use of resources, minimize bottlenecks, and meet delivery commitments.

Key Highlights:

- Real-time scheduling and rescheduling

- Capacity planning for machines, work centers, and manpower

- Visual Gantt charts and load balancing

- Priority-based job sequencing

- Integration with sales orders and inventory availability

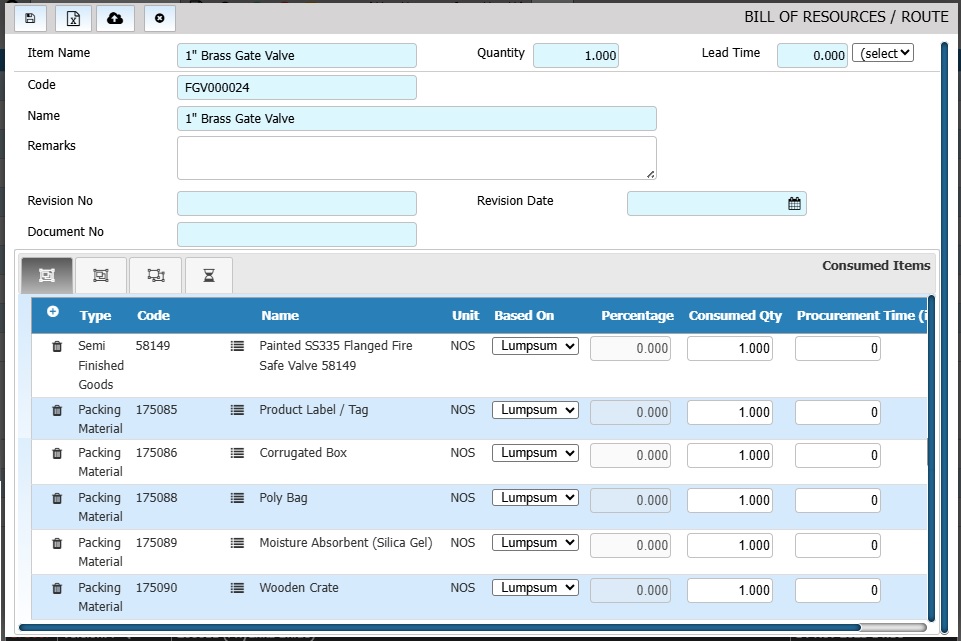

Bill of Materials (BOM) Management

Provides complete control over product structures, enabling multi-level BOMs, alternate material definitions, and revision management.

Key Highlights:

- Multi-level BOM creation & maintenance

- Alternate/Equivalent material and component support

- Phantom BOM and by-product tracking

- Routing-linked BOM consumption

- Version and revision-controlled BOM updates

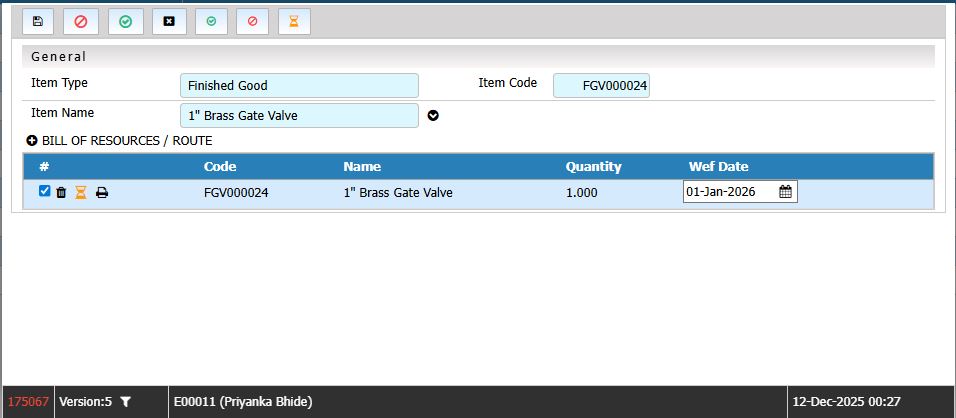

Engineering Change Request (ECR) & Engineering Change Note (ECN)

Automates the process of proposing, reviewing, approving, and implementing engineering changes in products and processes.

Key Highlights:

- Workflow for ECR creation, review & approval

- ECN issuance with effective date control

- Impact analysis on BOM, routing, costing, and inventory

- Controlled release to production & procurement

- Audit trail for design revisions

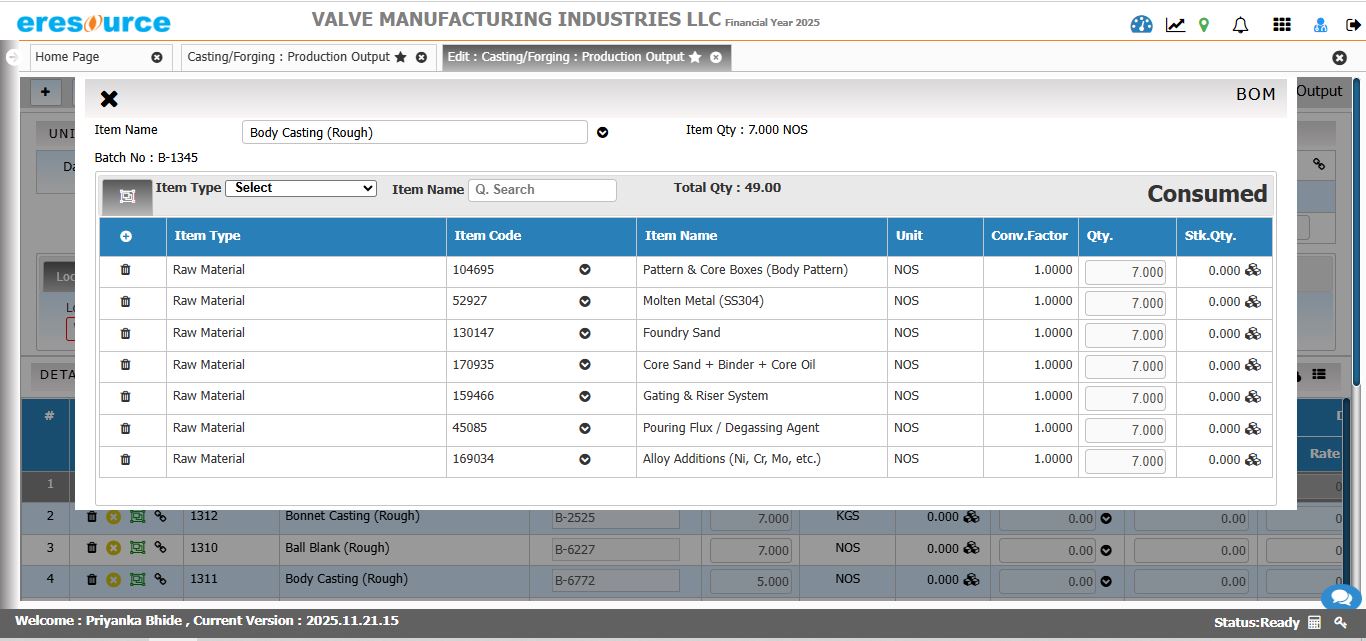

Production Routing Management

Defines and manages the operational steps required to manufacture a product, enabling precise planning and costing.

Key Highlights:

- Operation sequencing and work center assignment

- Setup time, run time, and labor standards

- Machine capability mapping

- Resource utilization analysis

- Links to production orders for cost roll-up

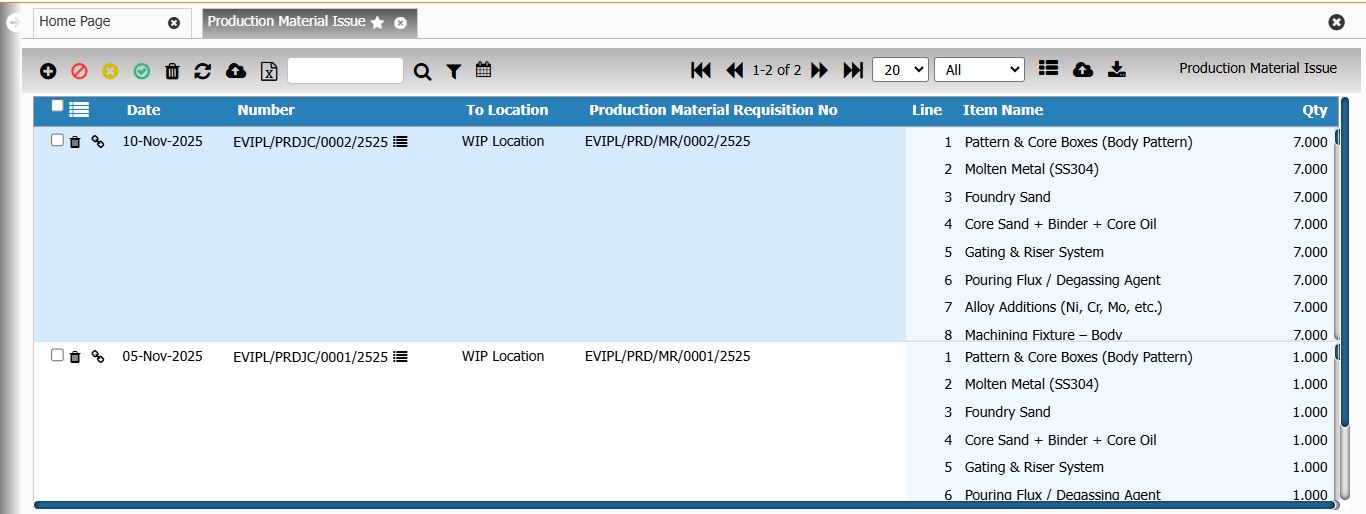

Inventory & Warehouse Control

Ensures accurate tracking of raw materials, WIP, and finished goods across multiple warehouses and locations.

Key Highlights:

- Multi-location & bin-level inventory

- Batch/Lot/Serial number tracking

- Automated re-ordering and replenishment

- GRN, Issue, Transfer, and Material Return management

- Cycle counting & real-time stock visibility

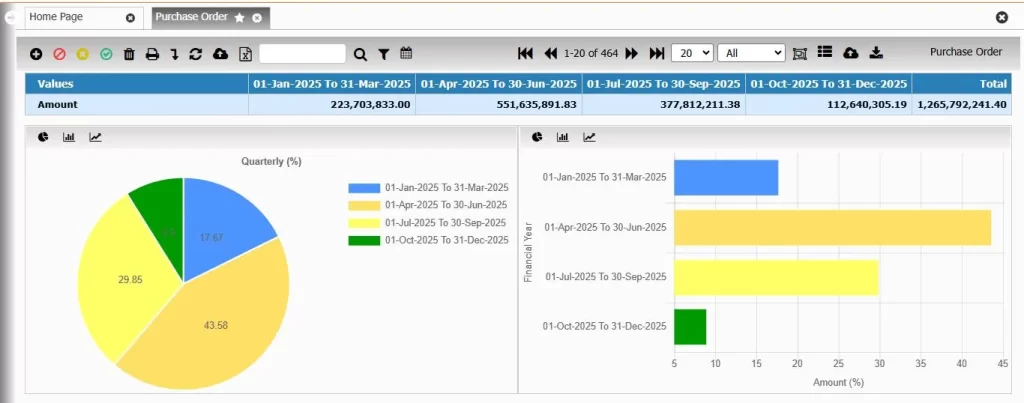

Purchase & Vendor Management

Streamlines procurement processes, vendor onboarding, and purchase controls to ensure uninterrupted material supply.

Key Highlights:

- Supplier qualification & rating

- Purchase requisition, RFQ, quotation comparison

- Purchase order, GRN, and invoice matching

- Contract & blanket purchase order management

- Vendor performance insights

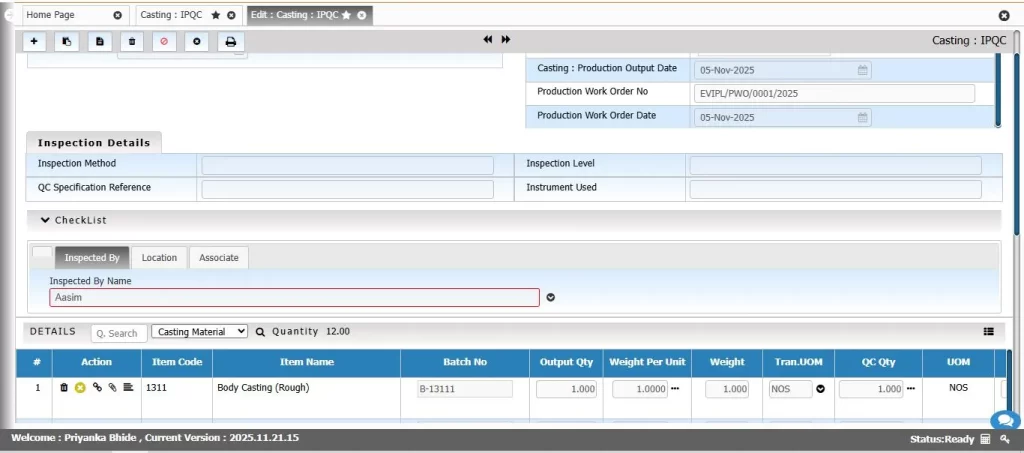

Quality Control & Assurance

Manages inspection processes and ensures adherence to quality standards throughout procurement, production, and dispatch stages.

Key Highlights:

- Incoming, in-process, and final QC checks

- Quality parameters & tolerance definitions

- QC sampling plans and auto-hold controls

- Non-conformance reports (NCR), CAPA management

- Certificates of Analysis (COA) & compliance documentation

Maintenance & Asset Management

Ensures continuous availability of critical equipment through preventive, predictive, and breakdown maintenance management.

Key Highlights:

- Preventive maintenance scheduling

- Breakdown reporting & root cause analysis

- Asset register with lifecycle tracking

- Spare parts & maintenance inventory control

- Maintenance cost tracking and reports

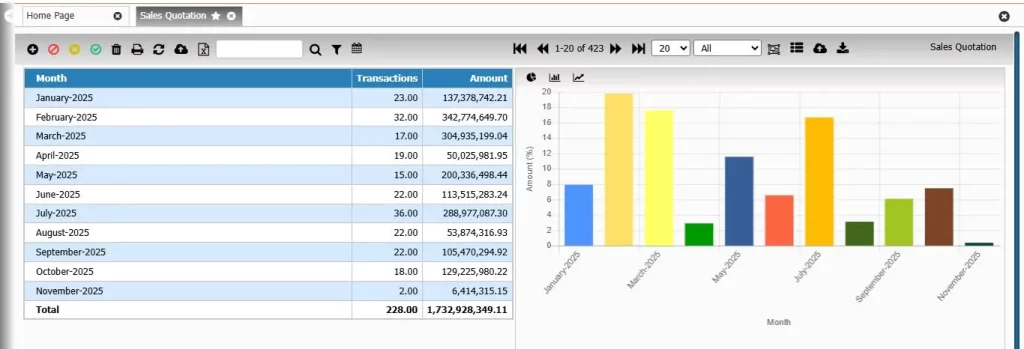

Sales & Order Management

Handles customer inquiries, quotation, order processing, and dispatch in a fully integrated workflow.

Key Highlights:

- Inquiry → Quotation → Sales Order lifecycle

- Pricing, discounts, and special condition management

- Delivery scheduling & shipment tracking

- Integration with production planning and inventory availability

- Customer-wise profitability tracking

Benefits for Steel Manufacturers

- Improve production yield and reduce scrap

- Gain real-time visibility of plant operations

- Ensure traceability and quality compliance

- Improve production planning accuracy

- Optimize asset utilization

- Enhance costing accuracy and profitability tracking

- Improve order fulfillment performance

- Scale production operations efficiently

Transform Steel Manufacturing with eresource Xcel ERP

eresource Xcel ERP transforms steel manufacturing operations by connecting plant processes, inventory, costing, and finance into one intelligent platform.

From billet processing to final dispatch, every operation becomes predictable, measurable, and optimized for business growth.

Case Studies

PolyPro Manufacturing

Reduced material waste by 12% through improved rework tracking and process optimization systems.

12% Less Waste

PlastiCore Industries

Improved machine uptime by 15% with predictive maintenance scheduling and real-time monitoring.

15% More Uptime

API Integrations

eresource ERP integrates with plant automation systems, logistics platforms, analytics tools, and enterprise applications for seamless data exchange.

IoT Integrations

Rolling mill machine monitoring

Furnace temperature sensors integration

Production line monitoring systems

Video Resources

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Frequently

Asked Question

Get answers to common questions about Steel Manufacturing Industry

Can eresource Xcel manage lot and heat number tracking?

Yes, full traceability is available across production stages.

Can ERP handle continuous and lot production?

Yes, both manufacturing models are supported.

Does the ERP manage scrap and yield tracking?

Yes, scrap and yield are monitored per production stage.

Can production planning be optimized across mills?

Yes, the system supports advanced production scheduling.

Is costing available per production lot?

Yes, profitability can be analyzed per product and lot.

Transform Steel Manufacturing with eresource Xcel ERP

Experience how eresource Xcel ERP streamlines production, inventory, quality, costing, and financial workflows for steel manufacturers.