AI-Driven Low-Code / No-Code ERP for the Lubricant Manufacturing Industry

Digitize formulation, batch processing, quality control, packing, and compliance — all in one enterprise platform.

Lubricant manufacturing is a precision-driven batch process industry. Every formulation, additive percentage, blending cycle, quality test, and packing step must be controlled — not just recorded.

With 20+ years of process manufacturing experience across 100+ industry types, eresource brings deep subject-matter expertise in:

- Lubricants & specialty oils

- Petrochemical derivatives

- Complex formulation-driven production

20 Years of Global Implementation Experience

eresource ERP has successfully implemented process and batch manufacturing ERP across India, UAE, Oman, Saudi Arabia, Qatar, Nigeria, Canada, Philippines.

Localized Taxation & Compliance Built In

Your ERP remains statutory-ready in every operating country.

🇮🇳 India

- GST Compliance

- e-Invoicing

- e-Way Bill

🇸🇦 Saudi Arabia

- ZATCA (Fatoora Phase-1 & Phase-2)

- VAT

- WHT

🇦🇪 UAE & Oman

- VAT compliance

- Audit-ready finance

🇶🇦 Qatar

- Withholding tax

- Audit trails

🇳🇬 Nigeria

- FIRS compliance

- Multi-currency accounting

🇨🇦 Canada

- Sales tax structures

- IFRS reporting

Powered by Azaalea AI Ecosystem

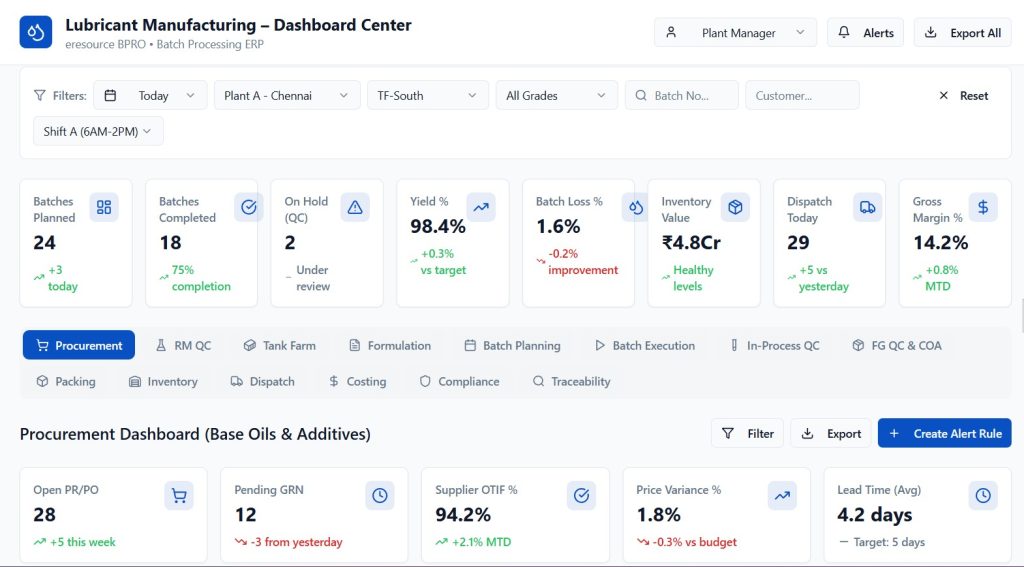

Complete Digital Control Across 9 Critical Stages

From raw material receipt to final dispatch — every step is system-controlled, traceable, and audit-ready.

Raw Material Procurement

PO, GRN, vendor management

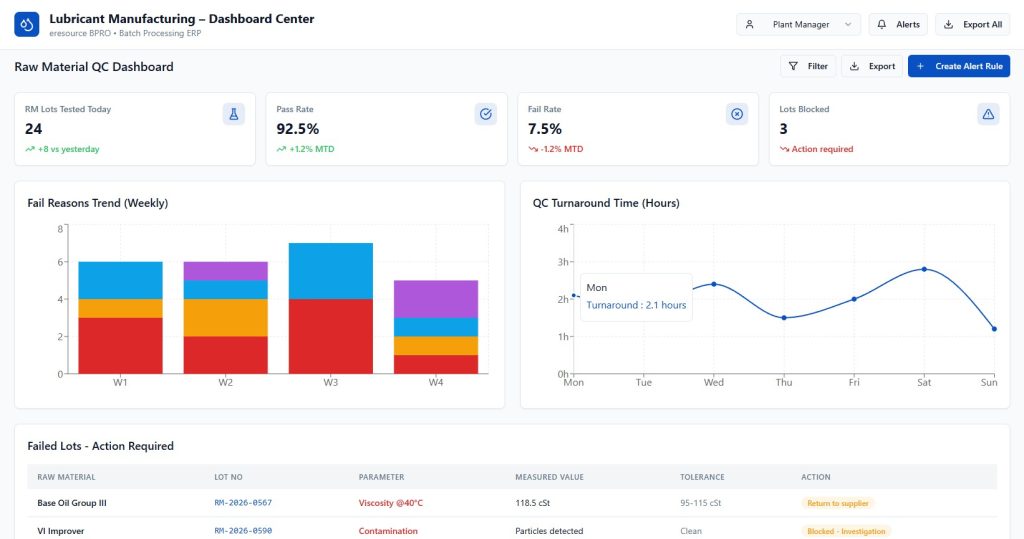

Inward Quality Inspection

Lab testing, lot approval

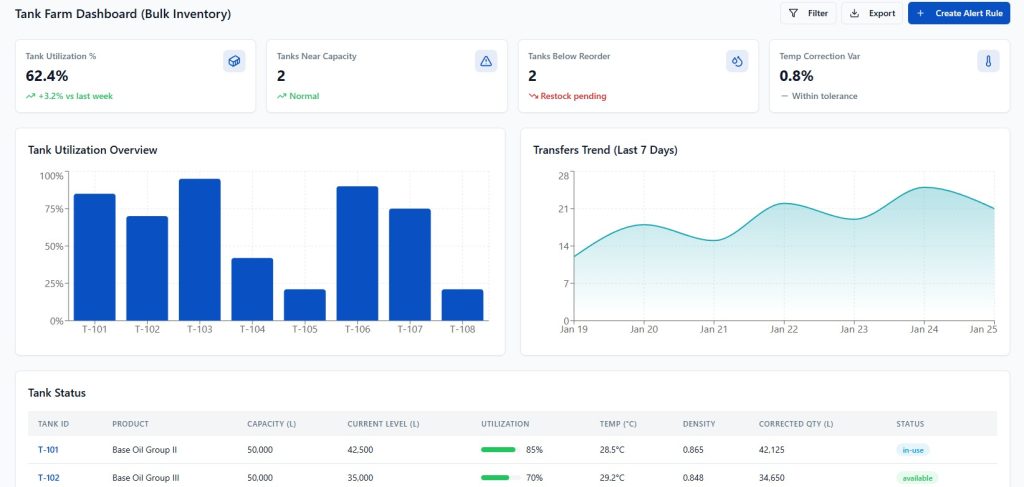

Tank Farm / Warehouse

Storage allocation, stock control

Batch Planning & Formulation

Recipe-driven production orders

Blending / Processing

Parameter control, yield tracking

In-Process & Final QC

Stage-wise quality gates

Packing & Labeling

SKU-wise packing, batch labels

Dispatch & Distribution

DO, e-way bill, logistics

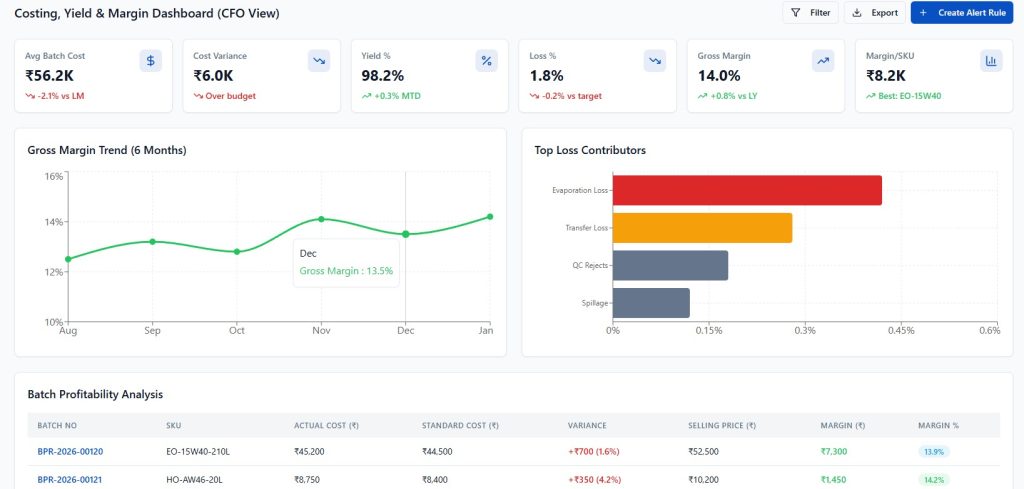

Costing & Margin Analysis

Yield variance, profitability

Core Manufacturing Modules

Comprehensive enterprise modules designed for lubricant manufacturing excellence

Raw Material Management

Manage base oils and additives inventory, QC approvals, and controlled issue to batches.

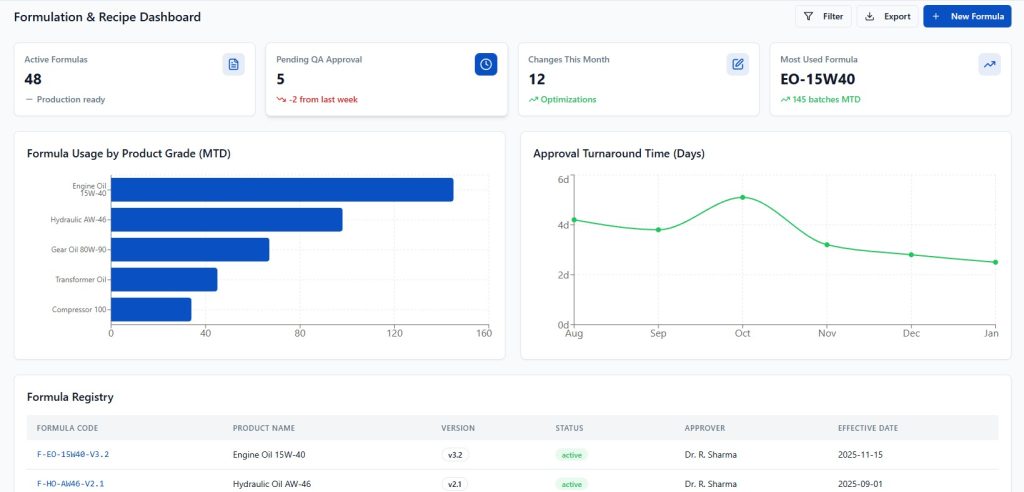

Formulation & Recipe Management

Multi-level recipes, percentage-based formulations, auto quantity calculation by batch size, substitute materials, version control, and QA approvals.

Batch Manufacturing

Automated batch creation, tank allocation, blending instructions, and production execution tracking.

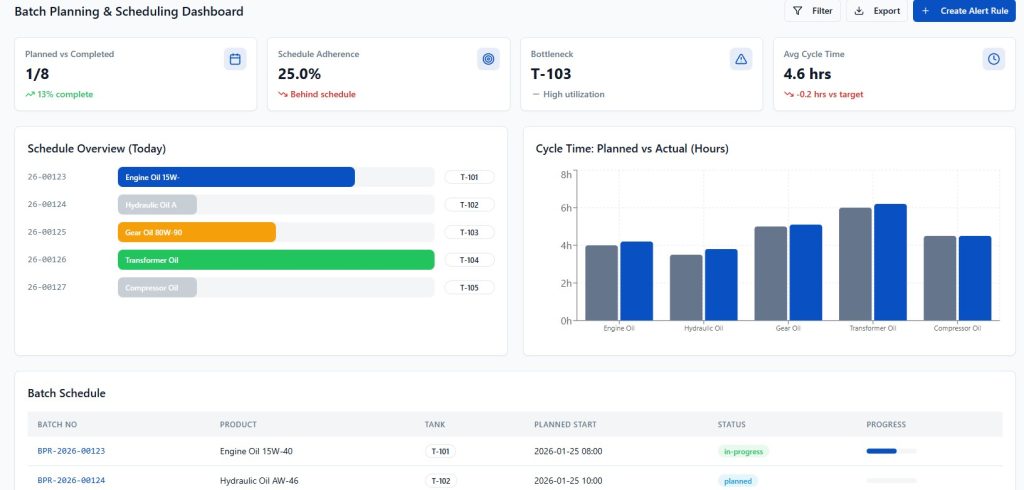

Production Planning & Scheduling

Plan batches, allocate tanks, machines, and manpower, optimize production cycles.

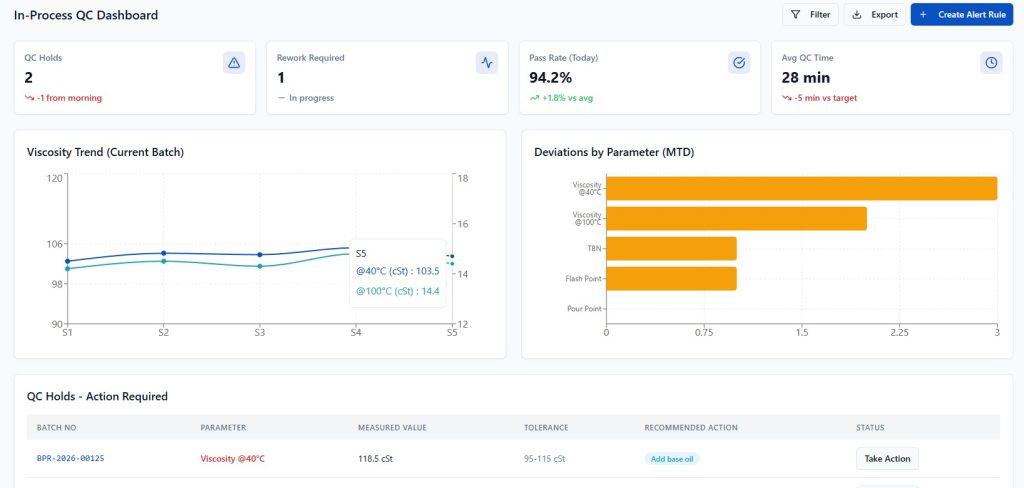

Quality Control (RM, In-Process, FG)

Integrated QC checkpoints, test parameters, approvals, and compliance documentation.

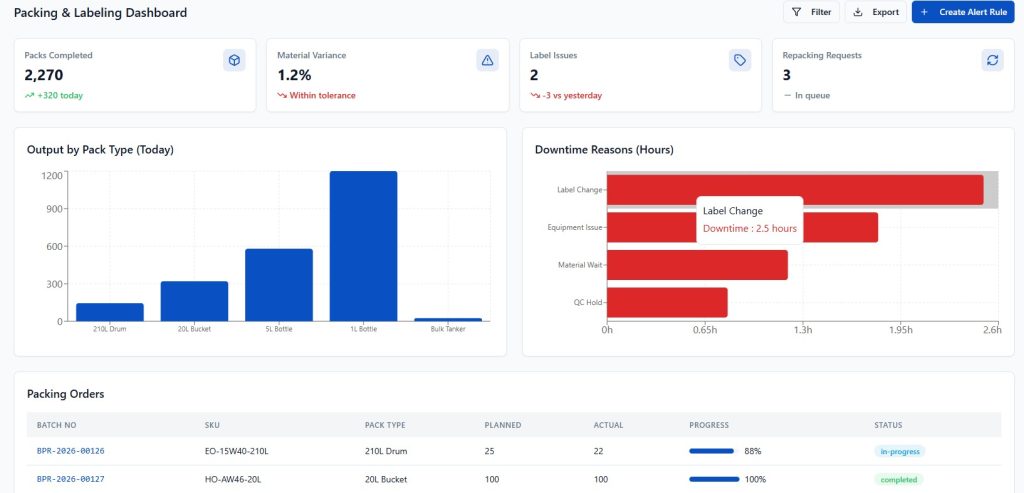

Packing & Labeling

Drum, bucket, bottle, or bulk packing workflows with label compliance control.

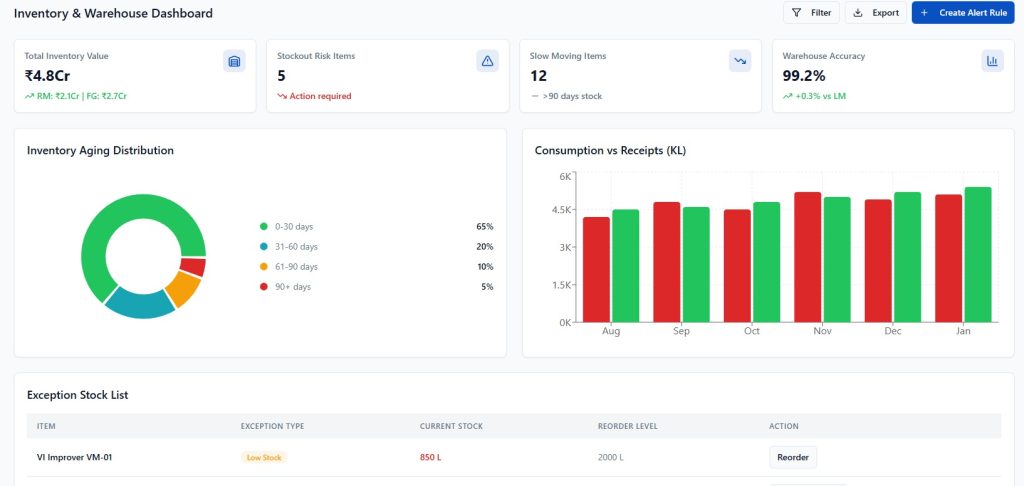

Inventory & Warehouse

Raw material, WIP, finished goods, and bulk tank stock management.

Costing & Finance

Batch-wise costing, yield tracking, margin analysis, and integrated finance.

Industry-Specific Add-On Modules

Specialized modules for lubricant and chemical manufacturing

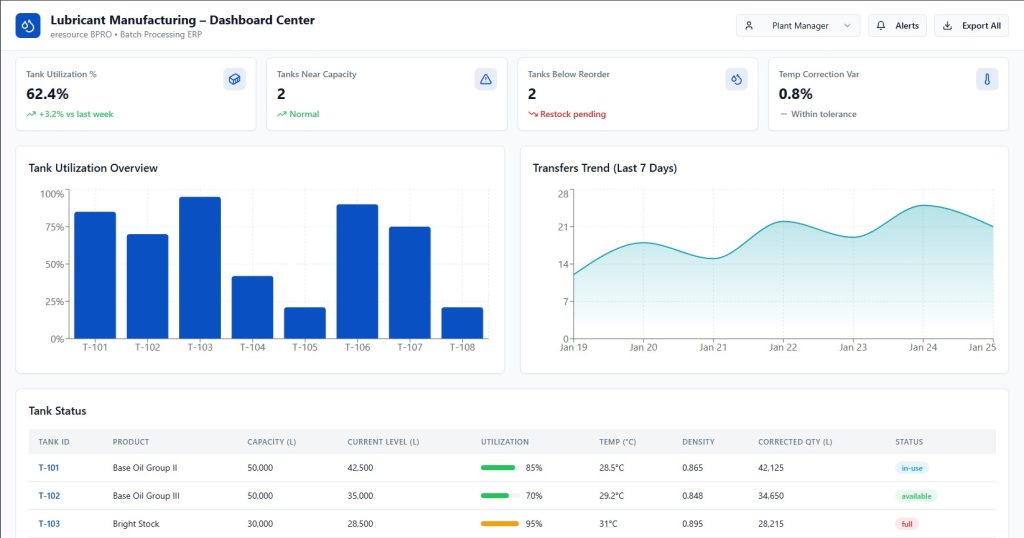

Tank Farm Management

Manage storage tanks, batch transfers, tank cleaning, and capacity utilization.

Additive Consumption Control

Track micro-additive dosing with precision-level accountability.

Yield & Loss Analysis

Monitor actual vs theoretical yield to reduce hidden losses.

Compliance & Statutory Module

Material Safety Data Sheets (MSDS), regulatory labels, statutory audit reports.

Sales, Dealer & Distribution

Dealer pricing, credit control, and distributor network automation.

Batch Traceability & Recall

Complete forward and backward batch traceability with recall readiness.

Why eresource BPRO for Lubricant Manufacturing

- 20+ years in process & batch manufacturing

- Built-in formulation intelligence

- Native ZATCA, GST, VAT, WHT compliance

- AI-driven production optimization

- IoT-ready for blending automation

- Full batch traceability

- Faster implementation with Low-Code / No-Code

Transform the Way You Manufacture with eresource Bpro

eresource Process Manufacturing ERP is not just software. It is a unified platform designed to power complex, batch-driven manufacturing businesses. With built-in automation, cloud-based access, and advanced analytics, it helps you gain full control over formulations, production, quality, and compliance.

From raw material planning to batch execution, quality checks, and finished goods reporting, every process becomes more controlled, traceable, efficient, and profitable.

Frequently

Asked Question

Get answers to common questions about AI-Driven Lubricant Manufacturing Industry

What type of manufacturing is supported?

All batch, process, formulation-driven, and hybrid manufacturing including paints, chemicals, lubricants, adhesives, and specialty formulations.

Does it support Saudi ZATCA e-Invoicing?

Yes, fully compliant with Fatoora Phase-1 and Phase-2 requirements.

Can ERP manage formulation recipes and version control?

Yes. BPRO is specifically designed for formulation-driven manufacturing with full version control, QA approvals, and audit trails.

Can ERP integrate with IoT sensors and blending equipment?

Yes, via our open IoT and API integration layer for real-time tank monitoring and blending automation.

How fast can implementation be done?

Powered by Low-Code / No-Code architecture — significantly faster than traditional ERP implementations.