One ERP. Every Industry. Global Presence. Powered by Azaalea AI

One ERP. Every Industry. Global Presence. Powered by

ERP Software for Automotive Industry

Advanced Automotive Manufacturing ERP Software for OEMs & Tier Suppliers

ERP Software for Automotive Industry

Advanced Automotive Manufacturing ERP Software for OEMs & Tier Suppliers

Automotive Manufacturing ERP Software

Built for Precision & Scale

The automotive industry demands speed, precision, and zero-defect quality.

Manufacturers produce:

- Engines and drivetrain components

- Body and chassis parts

- EV components and battery systems

- Plastic and metal assemblies

- Electrical and electronic modules

- Forgings, castings, and machined parts

Tier 1 and Tier 2 automotive suppliers must manage:

- Multi-level Bills of Materials (BOM)

- High-volume production lines

- Vendor coordination and JIT supply

- Tool and die management

- Quality audits and compliance standards

- Serial and batch traceability

- Preventive machine maintenance

- Production costing and margin control

Manual systems create production bottlenecks. Vendor delays increase. Quality traceability gaps appear. Cost visibility becomes weak.

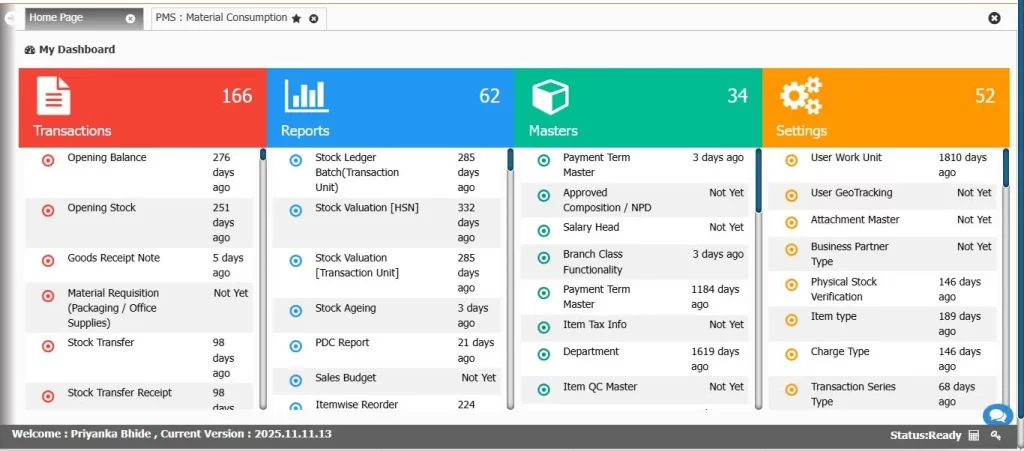

eresource Xcel ERP for Automotive Industry centralizes engineering, MRP, production planning, inventory, quality management, vendor coordination, maintenance, and finance into one integrated automotive ERP system.

It delivers real-time shop-floor visibility and complete production control.

Trusted by Leading Companies

Enquire Now

Fill out the form below to get in touch with us

Why Choose eresource Xcel ERP for Automotive Manufacturing?

Automotive production requires structured planning and strict compliance. Small errors in BOM, scheduling, or quality checks impact delivery commitments and profitability.

eresource Xcel ERP ensures automated and controlled workflows across automotive operations.

MRP & Production Planning

Plan high-volume production lines with real-time scheduling and demand forecasting.

Multi-Level BOM Management

Manage complex BOM structures with revision tracking and engineering control.

Shop-Floor Monitoring

Track WIP, machine utilization, output rates, and downtime instantly.

Quality Control & Compliance

Maintain in-process inspection logs, defect tracking, SPC, and audit documentation digitally.

Vendor & Supply Chain Management

Evaluate suppliers, manage procurement cycles, and ensure just-in-time coordination.

Inventory & Serial Traceability

Track raw materials, components, batches, serial numbers, and finished vehicles or assemblies accurately.

Preventive Maintenance Tracking

Schedule machine maintenance to reduce breakdowns and improve uptime.

Accurate Automotive Costing

Calculate material cost, labor cost, overhead allocation, and production variance precisely.

As a result, automotive manufacturers reduce defects and improve production efficiency.

Core Modules

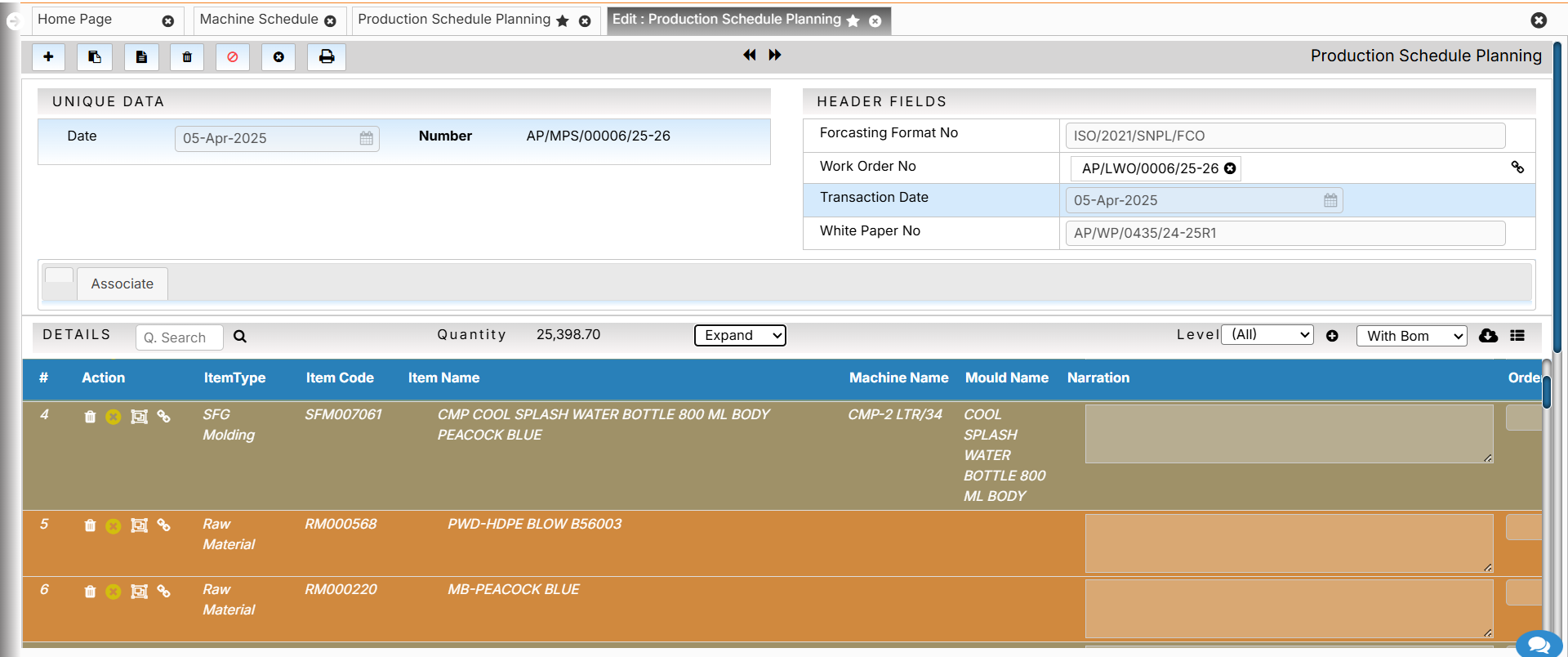

Production Scheduling

Enables efficient planning, sequencing, and allocation of production tasks to ensure optimal use of resources, minimize bottlenecks, and meet delivery commitments.

Key Highlights:

- Real-time scheduling and rescheduling

- Capacity planning for machines, work centers, and manpower

- Visual Gantt charts and load balancing

- Priority-based job sequencing

- Integration with sales orders and inventory availability

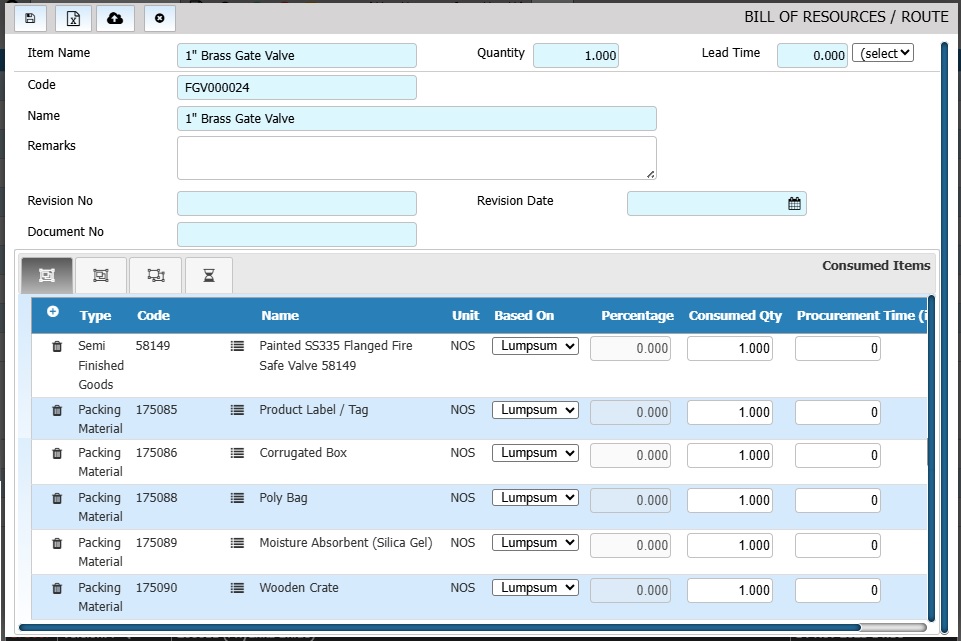

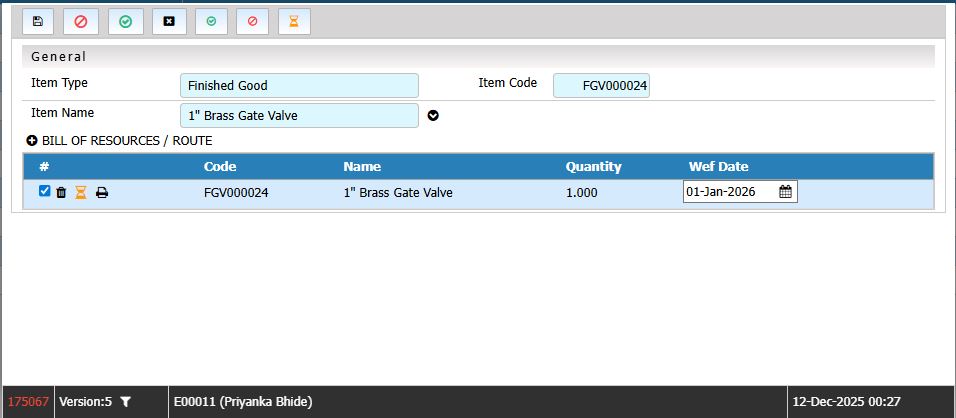

Bill of Materials (BOM) Management

Provides complete control over product structures, enabling multi-level BOMs, alternate material definitions, and revision management.

Key Highlights:

- Multi-level BOM creation & maintenance

- Alternate/Equivalent material and component support

- Phantom BOM and by-product tracking

- Routing-linked BOM consumption

- Version and revision-controlled BOM updates

Engineering Change Request (ECR) & Engineering Change Note (ECN)

Automates the process of proposing, reviewing, approving, and implementing engineering changes in products and processes.

Key Highlights:

- Workflow for ECR creation, review & approval

- ECN issuance with effective date control

- Impact analysis on BOM, routing, costing, and inventory

- Controlled release to production & procurement

- Audit trail for design revisions

Production Routing Management

Defines and manages the operational steps required to manufacture a product, enabling precise planning and costing.

Key Highlights:

- Operation sequencing and work center assignment

- Setup time, run time, and labor standards

- Machine capability mapping

- Resource utilization analysis

- Links to production orders for cost roll-up

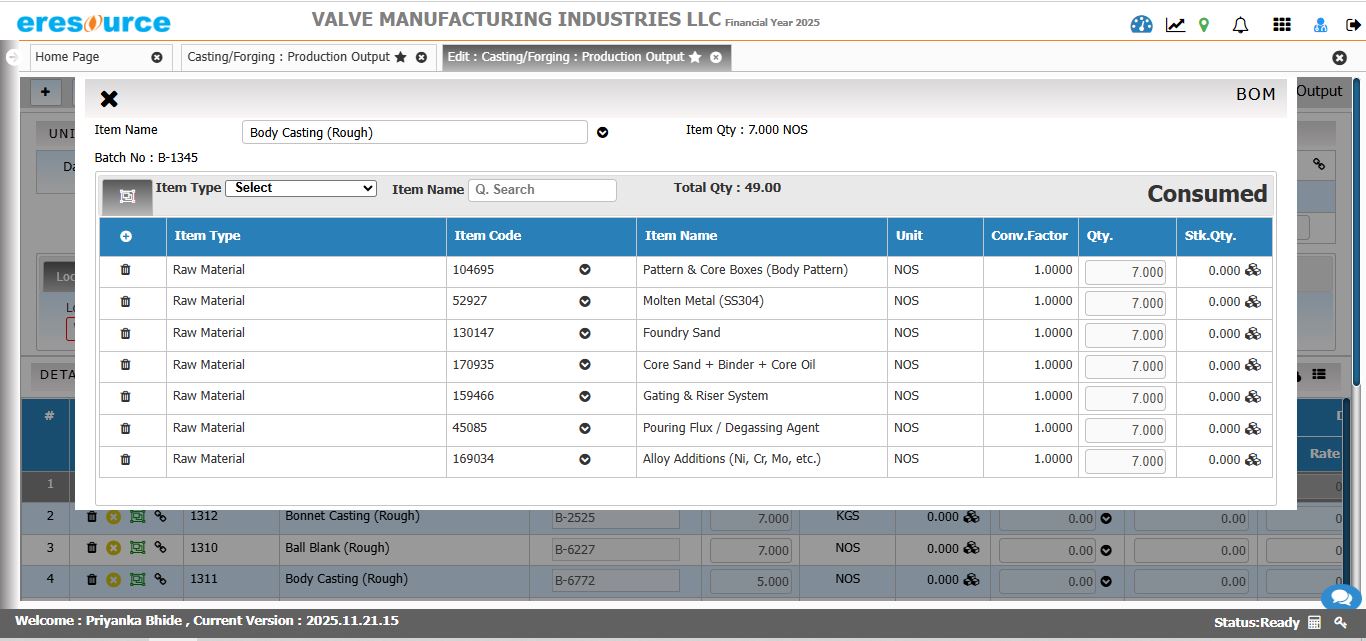

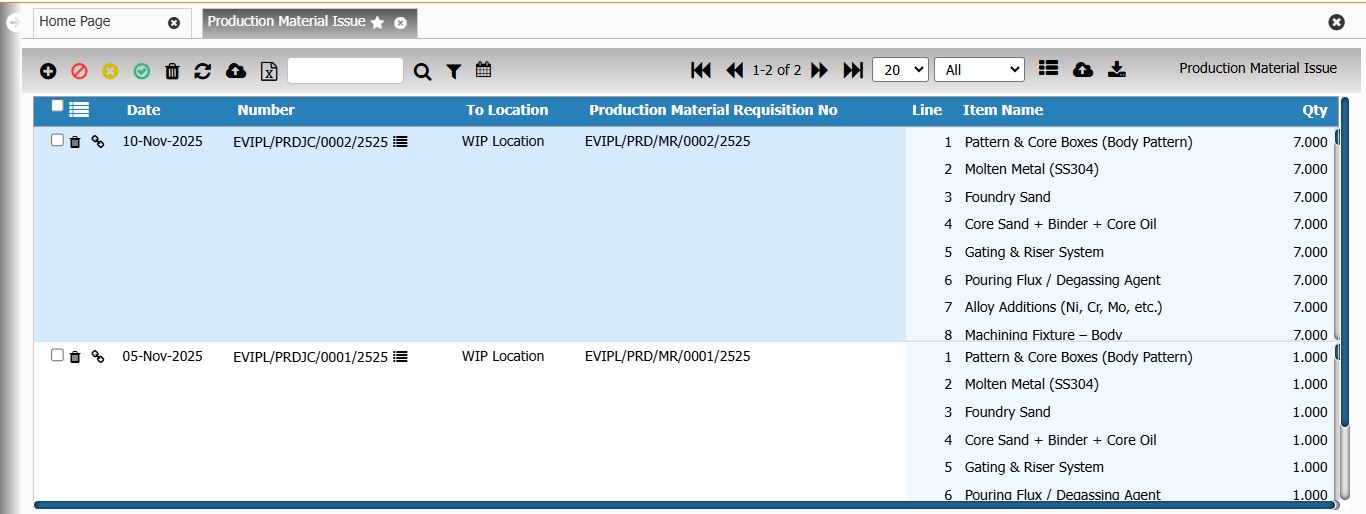

Inventory & Warehouse Control

Ensures accurate tracking of raw materials, WIP, and finished goods across multiple warehouses and locations.

Key Highlights:

- Multi-location & bin-level inventory

- Batch/Lot/Serial number tracking

- Automated re-ordering and replenishment

- GRN, Issue, Transfer, and Material Return management

- Cycle counting & real-time stock visibility

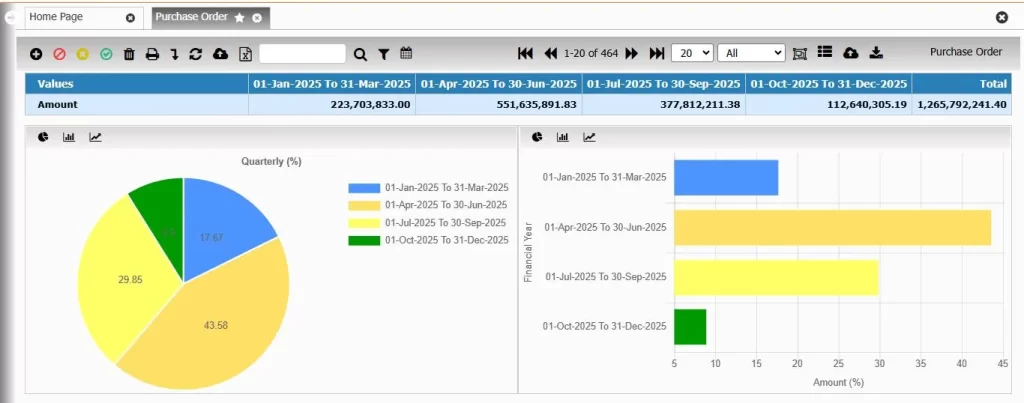

Purchase & Vendor Management

Streamlines procurement processes, vendor onboarding, and purchase controls to ensure uninterrupted material supply.

Key Highlights:

- Supplier qualification & rating

- Purchase requisition, RFQ, quotation comparison

- Purchase order, GRN, and invoice matching

- Contract & blanket purchase order management

- Vendor performance insights

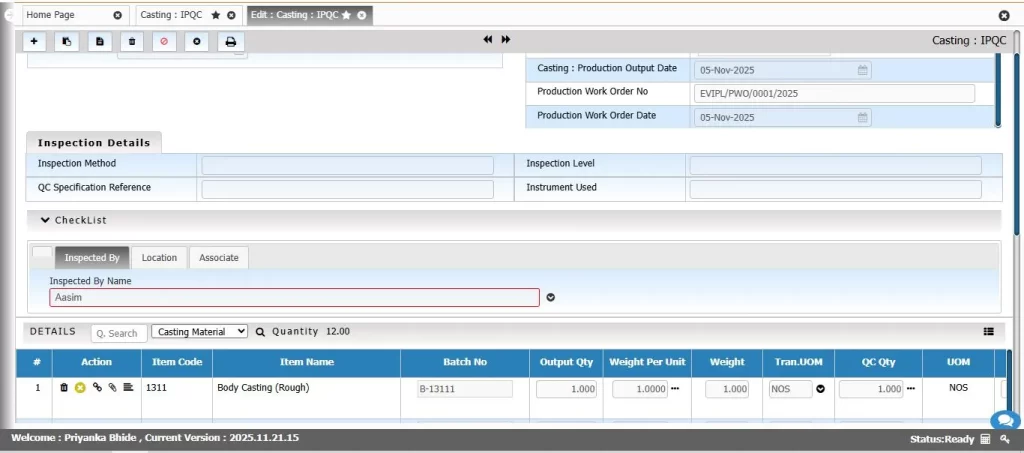

Quality Control & Assurance

Manages inspection processes and ensures adherence to quality standards throughout procurement, production, and dispatch stages.

Key Highlights:

- Incoming, in-process, and final QC checks

- Quality parameters & tolerance definitions

- QC sampling plans and auto-hold controls

- Non-conformance reports (NCR), CAPA management

- Certificates of Analysis (COA) & compliance documentation

Maintenance & Asset Management

Ensures continuous availability of critical equipment through preventive, predictive, and breakdown maintenance management.

Key Highlights:

- Preventive maintenance scheduling

- Breakdown reporting & root cause analysis

- Asset register with lifecycle tracking

- Spare parts & maintenance inventory control

- Maintenance cost tracking and reports

Sales & Order Management

Handles customer inquiries, quotation, order processing, and dispatch in a fully integrated workflow.

Key Highlights:

- Inquiry → Quotation → Sales Order lifecycle

- Pricing, discounts, and special condition management

- Delivery scheduling & shipment tracking

- Integration with production planning and inventory availability

- Customer-wise profitability tracking

Key Benefits for Automotive Companies

- Improve productivity with real-time production and shop-floor visibility

- Reduce defects through strong QA processes and complete traceability

- Optimize inventory levels and accelerate supply chain movement

- Strengthen vendor quality and procurement efficiency

- Maintain accurate costing and improve financial transparency

- Enhance machine uptime with preventive maintenance tracking

- Reduce operational delays with streamlined production workflows

- Support scalability across new models, product lines, and EV components

Built for Automotive Manufacturing Segments

- Xcel ERP supports:

- Automotive OEM manufacturers

- Tier 1 and Tier 2 suppliers

- EV component manufacturers

- Auto parts manufacturers

- Forging and casting units

- Plastic and metal component manufacturers

- Wiring harness and electrical assembly units

- High-volume production environments

Unlike generic ERP software, Xcel ERP is built specifically for automotive production and supplier ecosystems.

How Automotive ERP Improves Profitability

Automotive manufacturers often struggle with:

- Excess inventory

- Production delays

- Vendor dependency risks

- Quality rejections

- Compliance challenges

- Cost leakage

However, with eresource Xcel ERP:

- Every production stage is tracked

- Every supplier is evaluated

- Every defect is recorded

- Every machine is monitored

- Every cost is calculated accurately

Therefore, manufacturing becomes predictable and margins improve.

Advanced Manufacturing Capabilities

High-Volume Production Management

Support continuous production lines with demand-driven scheduling.

Just-in-Time (JIT) Supply Coordination

Ensure materials arrive as per production requirements.

Batch & Serial Traceability

Enable full traceability for compliance and recall management.

Multi-Plant Operations

Manage multiple manufacturing plants under one centralized system.

Case Studies

AutoAssembly Corp

Achieved 99.8% on-time delivery with integrated production planning.

99.8% On-time Delivery

VehicleTech Manufacturing

Reduced quality defects by 45% with comprehensive tracking systems.

45% Defect Reduction

API Integrations

APIs to integrate with other enterprise, analytics, finance, or planning systems as per business needs.

Seamless connectivity with OEM systems, supplier networks, and regulatory platforms for unified operations.

IoT Integrations

Assembly line sensors for real-time monitoring

Quality testing equipment integration

Vehicle tracking and traceability systems

Video Resources

The Real Reason Leading Auto Companies Invest in Automotive ERP Software

AI Integration vs Agentic AI: The Future of Smart ERP for Faster & Accurate Business Operations

ERP Readiness Checklist: Is Your Business Prepared for Digital Integration in 2025?

Here’s why eresource ERP implementation is always successful ?

Can eresource Xcel ERP manage multi-level BOMs for automotive parts?

Yes. The ERP supports complex BOM structures, subassemblies, and engineering changes required in automotive manufacturing.

Does it include strong quality control features?

Absolutely. It covers incoming, in-process, and final QC along with defect analysis and traceability.

Can it integrate supplier performance and vendor rating?

Yes. The ERP tracks vendor deliveries, quality scores, rejections, and price performance.

Does the system support shop-floor production tracking?

It does. Real-time production updates, job cards, and machine utilization reports ensure accurate monitoring.

Is the ERP suitable for tier 1 and tier 2 automotive suppliers?

Yes. It is built for OEM suppliers, component manufacturers, and automotive production units of all sizes.

Can eresource Xcel support EV manufacturing workflows?

Yes. The system can manage EV components, batteries, assemblies, and new product lines seamlessly.

Achieve Seamless Automotive Production and Supply Chain Coordination

Experience how eresource Xcel ERP enhances efficiency, quality, and financial control across every stage of your automotive operations.